With Next Open Automation (NOA), KEB Automation is presenting a new IIoT and Edge platform for the collection, visualisation and processing of data. Use cases such as predictive maintenance can be implemented with NOA to protect plant and machine builders from unforeseen costly downtime. The platform enables users to design their own automation solutions flexibly and easily on the basis of ‘open’ systems.

Industrial automation is changing. This is accompanied by fundamental requirements such as more flexibility and simplification. Systems are becoming increasingly ‘open’ for cooperation between different manufacturers. For plant and machine builders, this reduces development effort and the dependence on one product or supplier. This results in more opportunities to flexibly integrate their own functions into systems. Solutions optimised in this way can strengthen a machine builder’s own portfolio in the market.

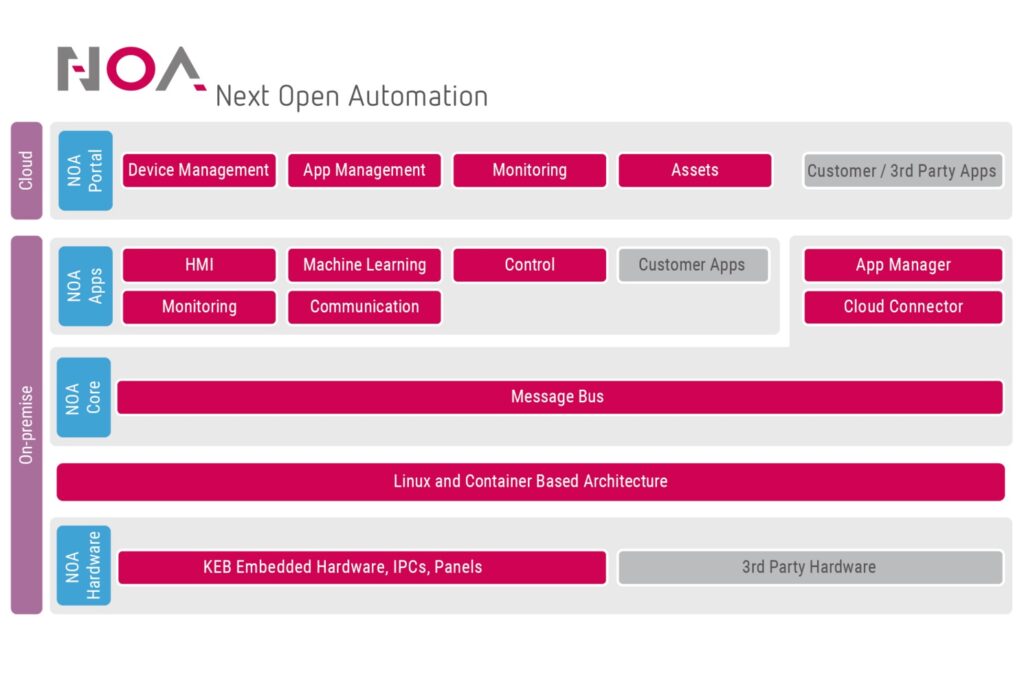

At the SPS trade fair in Nuremberg (14-16 November 2023), KEB Automation presented its new NOA (Next Open Automation) solution to a wide audience for the first time. NOA makes it easier for machine and plant manufacturers to individually integrate functionalities into the system. KEB’s platform is based on microservices and can be supplemented by hardware and software components from KEB. Container-based apps such as solutions for HMIs, machine learning, monitoring and controls, as well as customer-specific apps, can be managed on the Edge via the App Manager.

Similar to a smartphone

The cloud-based NOA Portal provides the higher-level services such as device management. The core infrastructure, NOA Core, relies on a Linux- and container-based architecture and can be used on embedded hardware, IPCs and panels from KEB or third-party devices. Overall, NOA works in a similar way to a smartphone: here too, it is not necessary for users to install all the apps from the store – they can configure their smartphone with the apps individually, in accordance with their own particular needs.

“NOA follows a very open and flexible approach,” says Uwe Huber, Head of HMI and IIoT Development at KEB. “On the software side, the user can add KEB apps as well as their own third-party apps and therefore access all available data. On the hardware side, the system can run on both KEB and third-party devices.” Among other things, the HELIO HMI management system is also available as a NOA app. HELIO enables the platform-independent visualisation of plant and machines. Web-based HMI or SCADA applications can be created easily and quickly without the user requiring any programming knowledge. The display is flexible and can be used on different target devices.

On the hardware side, for example, the new C6 COMPACT 3 embedded controller from KEB Automation, which is designed for applications with low to medium complexity, represents a suitable addition within the platform solution. The C6 X1 HMI panels with IP67 protection class and Power-over-Ethernet (PoE) are also suitable.

“The available apps cover standard use cases such as predictive maintenance, visualisation, monitoring and data collection,” continues Huber. “Here, data can be acquired locally through and Edge system on site. Optionally, these can be collected, visualised, analysed and optimised in the cloud by means of a corresponding connection.” Quality indicators can be calculated by the user and insights can be gained from the data. The data collected by NOA is used for machine monitoring and, if necessary, alarms can be set up.

The HMI management system HELIO is already available from KEB and the hardware components will follow soon. The launch of NOA as a complete solution is planned for 2024.

For more information, please visit www.keb.co.uk