Ordering a taxi or an Uber via your smartphone is a relatively simple task, but calling a train to you whenever you need it is surely impossible? A project being undertaken by the OWL University of Applied Sciences and the Landeseisenbahn Lippe e. V. Association aims to demonstrate that this is in fact possible. The project involves the development of a monorail vehicle – the MONOCAB – for the public transport of the future. Onboard this innovative means of transport is a range of drive solutions from KEB Automation.

The MONOCAB uses servo motors and drive controllers from KEB, as well as the T6 APD modular inverter system with integrated power electronics.

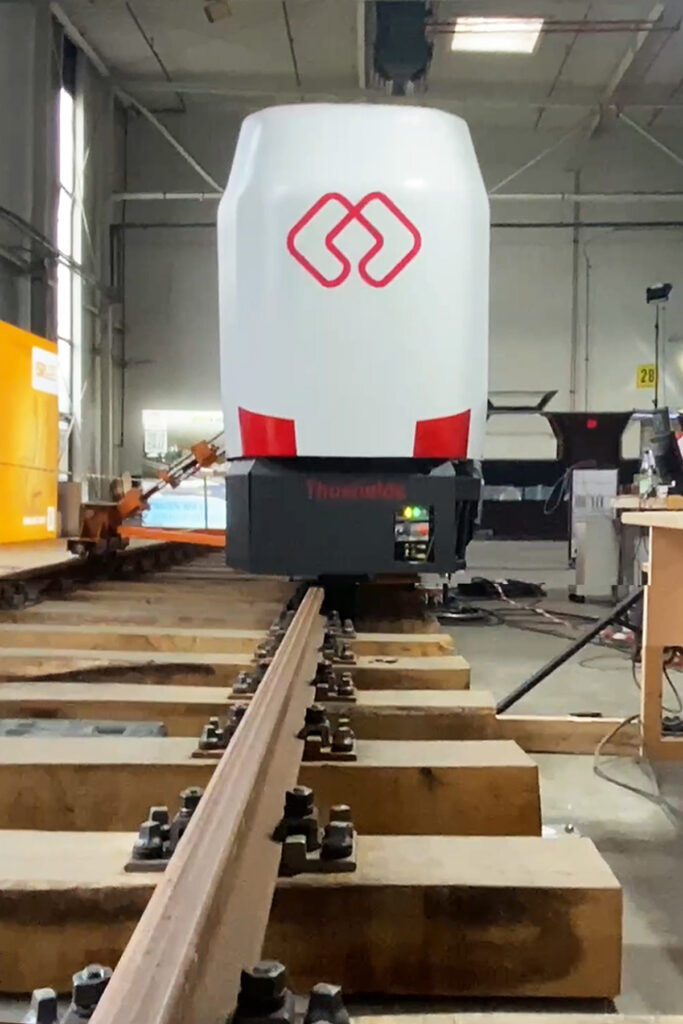

Behind the MONOCAB is a driverless cabin for up to eight people, which will travel on a single rail. And to some extent it already does: several successful test runs on the historic single-track railway line between Lemgo and Extertal in Germany have already given an impression of what mobility could look like in the future. A particular focus is on promoting local public transport in rural areas. This is because there are many single-track lines here that are not currently in use. The MONOCAB aims to revitalise these tracks.

One of the special goals of the project: as the vehicle moves on only one side of the track, two MONOCABS can travel at the same time in each direction. The very narrow vehicles are given stability by an innovative combination of actively-controlled gyroscopic systems with a moveable mass that balances the vehicle during travel. Finally, the cabs are to be in continuous circulation and can be conveniently ordered via app to increase individual mobility in rural areas.

KEB components in the MONOCAB

KEB Automation also has an exciting role in the project. With servo motors, the T6 APD and the COMBIVERT S6 drive controllers, several components are used in the MONOCAB. “The control of the traction drives is handled by our modular inverter system, the T6 APD. The S6 inverters and the servo motors, on the other hand, are needed to support the stabilisation of the cabin,” says Daniel Schröder, Application Engineer for control technology at KEB, who is involved in the project. One of the reasons why KEB products were chosen for the MONOCAB was the possibility of the CAN bus interface that enables communication between inverters and control units, reports Martin Griese, research assistant at the OWL University of Applied Sciences.

The T6 APD modular inverter system from KEB.

The T6 APD was developed specifically for the automotive environment and is therefore also a good choice for the MONOCAB. “Important in this application is a high protection class, vibration and shake resistance. As the vehicle is exposed to weather, durability and robustness play a major role. And the T6 fulfills exactly this,” says Schröder.

About the T6 APD The T6 APD is a scalable and modular inverter system with integrated power electronics, intelligent mobile control unit and EMC filter solutions. It converts direct current from the HV-DC source into three-phase current for driving electric motors. The system meets all the requirements placed on

electronic components for the automotive sector – in terms of mechanical and thermal properties, environmental conditions, safety and service life. The T6 system can be flexibly adapted to different vehicle requirements and enables the integration of up to six inverter modules, which are available in three power levels with rated output currents of 16.5A, 33A and 60A. The T6 APD takes over the power supply of the inverter modules as well as the dynamic and energy-efficient speed and torque control.

The system supports all motor types such as synchronous and asynchronous motors, IPM motors and synchronous reluctance motors and does not require encoder feedback. Two CAN ports are available for communication, supporting all common CAN protocols such as J1939 or CANopen. With the latest software version, the T6 APD also supports the UDS diagnostic protocol on the CAN bus. Based on a collection of different services within the protocol, almost all available parameters can be read and written. Error memories can be read out or deleted. It is also possible to transfer files and software via the UDS interface.

As the vehicle moves on only one side of the track, two MONOCABS can travel at the same time in each direction.

The fact that the MONOCAB uses a KEB system solution consisting of inverters and motors ensures the best possible performance of the individual components and also simplifies commissioning. KEB’s service colleagues can also commission the motor directly on site and carry out fine-tuning or, if necessary, provide direct online support using remote maintenance tools. Daniel Schröder: “We are pleased to be able to contribute our know-how in drive and automation technology to the MONOCAB project and thus play a part in literally setting the track for the local transport of the future.”

For more information, please visit www.keb.co.uk