Precision performance servo gearbox specialist Apex Dynamics is on hand at Automation UK 2024 to demonstrate the wide range of applications for its products and promote its industry-leading service.

Apex Dynamics is exhibiting at Automation UK 2024, with its team of expert engineers showcasing the company’s complete portfolio of gearboxes, geared motors, and rack and pinion sets. The motion control specialist is appearing at the UK automation and robotics expo at the CBS Arena in Coventry on 18th and 19th June to meet with potential customers and talk to them about their servo gearbox needs. Automation UK is co-located with the UKIVA Machine Vision Conference and is one of the largest annual gatherings of industry experts in the UK.

With its continually expanding portfolio of automation solutions, Apex Dynamics’ unique offering includes five pledges that are unmatched in the market. These are patented designs, 5-year warranties, fast 2-3 week lead times, guaranteed delivery and ATEX as standard. Manufactured from the highest quality materials, Apex Dynamics products are robust, reliable and with a long service life.

Demonstrations, expertise and a wide range of solutions at the Apex Dynamics stand

The Apex Dynamics stand (E14) at Automation UK 2024 will feature immersive displays and demonstrations, as well as details of a wide range of the company’s products and solutions, including:

BKM Series Geared Motors: The high efficiency BKM hypoid gearbox range complements Apex Dynamics’ wide range of planetary gearboxes. It has been introduced in response to customer demand and the need to reduce energy consumption.

G Series Geared Motors: The highly adaptable, compact G-series of helical gearboxes and geared motor units delivers enhanced performance, reliability and load capacity, alongside low noise and a long service life. The high-performance gearboxes and geared motor combinations can be used with a variety of different types of motors, combined into mechatronics and connected in a range of installation positions.

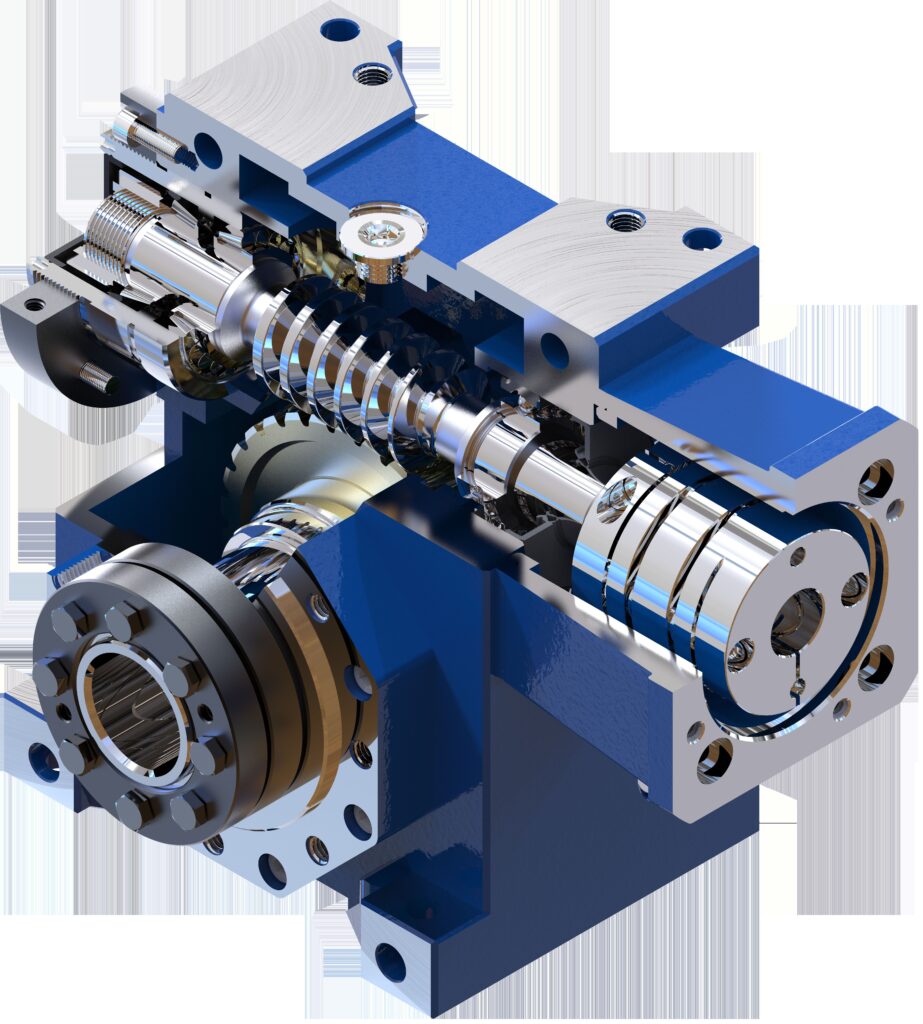

JDLB Servo Worm Gearboxes: Apex Dynamics’ robust Servo Worm gearbox range is ideal for reliable precision rotary motion. Comprising J, D, L and B variants, customers can adjust the worm shaft for worm gear gyration backlash of less than 1 arc minute, reducing noise, vibration and movement from load changes, speed changes, cutting, corotation, and reverse.

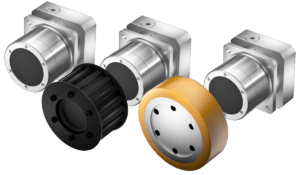

GL Series for AGV applications: Thepopular high precision Apex Dynamics GL/GLS series of planetary gearboxes is ideal for robotics, AGV and AMR applications, providing low noise, long service life, optimised output torque, heavy radial load capacity up to 7,200N, and low backlash. The unique rotary housing enables a drive wheel or pulley to be mounted over the exterior.

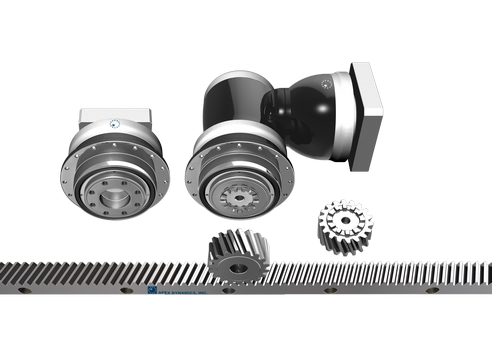

MD / MF High Performance Planetary Gearboxes: The compact MD series high precision rotary flange style planetary gearbox and the MF series in line servo gearbox provide excellent value and high axial and load capacity, with case hardened and ground planet gears for high accuracy and increased wear resistance for high cycle rates. The MD/MF range really packs a punch.

Rack and Pinion Systems: Apex Dynamics’ rack and pinion systems are manufactured to meet Quality 4 standards and deliver high precision, low noise, high speed, very low tolerance, higher force capability, long life and high performance on the axis. Systems are tooled underground to ensure the best possible temperature control and quality.

Smart Lubrication Systems: Complementing Apex Dynamics’ range of transmission devices and rack and pinion systems, smart lubrication systems prevent oxidation and reduce wear. The LUG Smart Lubrication Pumps provide metered automatic lubrication for optimal life.

High performance, precision, reliability and customer support

Expert engineers from Apex Dynamics UK work with customers to identify the ideal solutions for their specific needs and applications. Recent high-profile projects including supplying components to the largest electricity-generating waterwheel in Europe, now in operation, and being selected by the world’s biggest manufacturer of rotary devices, RPI UK, for excellent delivery times, low noise and high performance.

As part of its commitment to helping customers choose the ideal servo gearbox and motor combination to meet their specific needs, Apex Dynamics recently unveiled its innovative Dynamax 2 online design tool, which delivers precise results for optimal servo gearbox and motor combinations, empowering engineers and designers to make informed decisions. Accessible via the Apex Dynamics website at www.apexdnauk.com, Dynamax 2 has an interactive, fast, and intuitive interface that meets the needs of diverse applications and systems and provides crucial safety factor information for users. The solution allows users to fine-tune their designs based on both optimal performance and enhanced safety for a comprehensive, holistic approach to the design process.

Speaking ahead of Automation UK 2024, Mike Gulliford, Managing Director of Apex Dynamics UK, says, “We are constantly refining and expanding our product range and exploring new ways of supporting our customers to get the best performance from their applications. Automation UK 2024 provides the ideal opportunity to showcase the capabilities and performance of our precision gearboxes and solutions.

“The team and I are very much looking forward to meeting with industrial OEMs and manufacturers to demonstrate how we can enhance their operations by providing the best mix of high performance products, excellent customer service, fast delivery times and product guarantees on the market. We have huge confidence in our portfolio and service and are enthusiastic about promoting Apex Dynamics UK, so if you are attending Automation 2024 and would like to arrange a meeting with our expert engineers at the stand (E14), please get in touch with me directly on [email protected] or stop by and see us.”