Motion Control Products Ltd (MCP), motion solutions provider for the automation market, introduces high quality, high precision Slotless BLDC motors.

What is Slotless BLDC Motor?

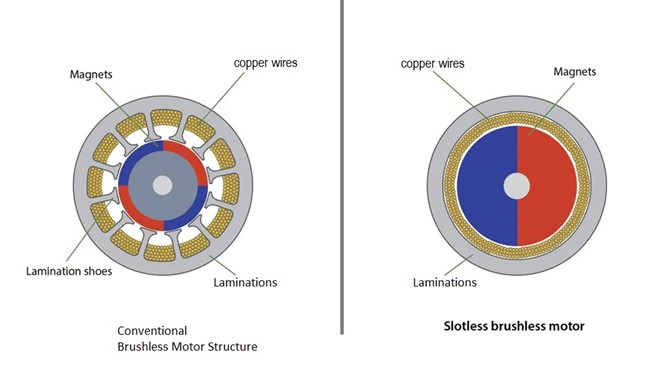

In contrast to traditional slotted BLDC motors, slotless BLDC motors take a different approach in the motor design: Instead of winding copper wire through lamination slots, it is wound into a cylindrical shape, offering enhanced protection and rigidity. This “slotless” configuration overcomes the problems of air gap magnetic induction pulsating issues. This phenomenon is typically caused by irregular magnetic resistance in toothed motors, resulting in undesirable vibrations and inefficiencies.

In a slotless BLDC motor, copper wire is wound into a cylindrical shape and protected, rather than being wound through lamination slots as in conventional slotted BLDC motors. This design eliminates the need for a slotted stator lamination stack, ultimately reducing cogging, vibration, and noise. Additionally, the rotor can have a larger diameter, which therefore increases the torque.

The absence of teeth in a slotless motor reduces winding inductance and decreases damping for faster motor response. This results in less electromagnetic interference, making slotless motors suitable for high-speed and fast acceleration and deceleration applications.

Benefits of Slotless BLDC Motors

- Cogging Elimination: The absence of stator teeth eradicates cogging, ensuring smoother operation in the application.

- Reduced Noise: Slotless BLDC motors operate quietly, thanks to low-loss lamination materials.

- Enhanced Efficiency: Reduced damping losses lead to improved efficiency.

- Faster Response: Lower winding inductance enables rapid dynamic responses.

- Vibration Minimisation: These motors experience minimal vibration, enhancing precision running.

- High-Speed Operation: Ideal for high-speed applications like drilling.

- Customisation: Easier winding customisation to suit specific customer needs.

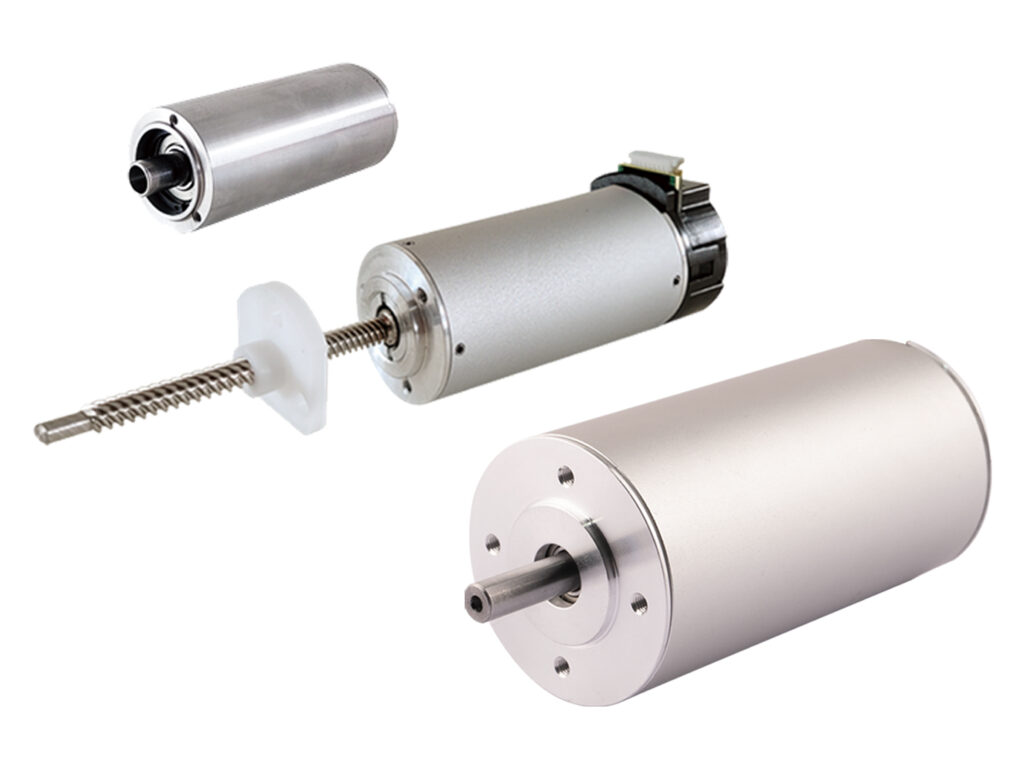

As DINGS’ Motion official UK business partner, Motion Control Products offers a diverse range of slotless BLDC motors, available in multiple sizes to cater to various dimensional requirements. The motor diameters are available in 10mm, 16mm, 22mm, 28mm, 36mm and 42mm. Even smaller-sized motors can achieve impressive performance, voltages from 12V to 48V, 1 or 2 pole pairs, with powers of up to 200 watts, and a maximum loaded speed of 50,000 RPM and up to 91% motor efficiency. Motion Control Products range of slotless brushless dc motors is tailor-made for servo systems that demand fast movements and robust power delivery.

With the added advantage we can provide the flexibility to enhance the motor’s capabilities with optional features:

1. High Precision Planetary Gearbox: For precision control and increased torque.

2. High-resolution Encoder: For accurate position and speed feedback.

3. Matched compact BLDC drives: These drives are offered with the motor to complement the range

4. Lead Screw Actuator Format: To assist on linear motion applications, our innovative slotless brushless DC actuator concept emerges as an ideal solution in response to market demand, particularly for vertical-axis applications or as a pneumatic cylinder replacement.

Typical applications for a slotless BLDC motor include high-speed drilling, medical devices such as angioplasty equipment, medical imaging equipment, scanners, miniature pumps, testing equipment, measuring equipment, laser beam reflector rotation, fluid dispensing in medical pumps, and aircraft control systems.

MCP commitment extends beyond quality motors. We offer competitive pricing and comprehensive technical support for both motors and motion control solutions. Custom design is available upon request to meet your specific requirements. For more information about our new slotless brushless motors and how it can elevate operations in challenging conditions, please visit our website.