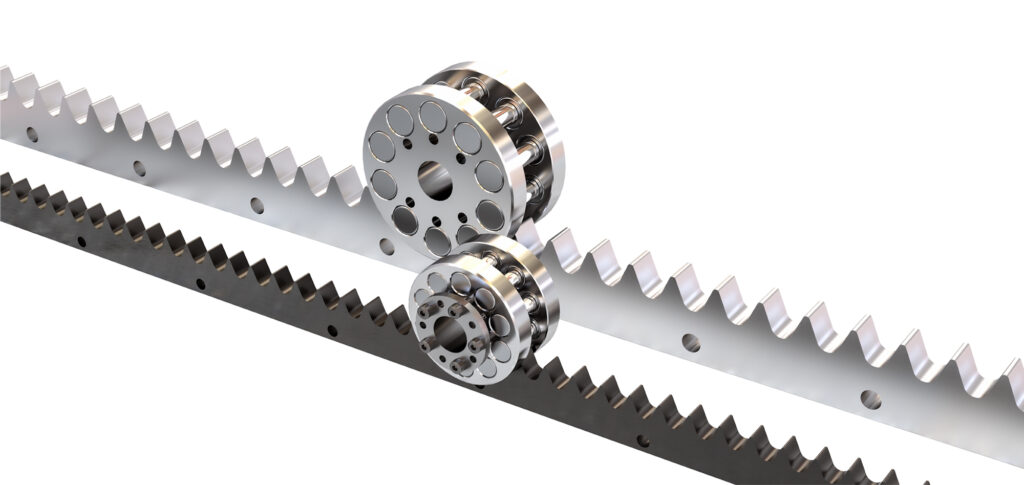

Nexen Group’s 32 mm and 40 mm Roller Pinions have been re-engineered with new needle bearings to handle higher torque loads while delivering high accuracy with zero backlash.

Nexen’s 32 mm Roller Pinion is the same size as the previous version but has a 66 percent increase in torque while maintaining its inertia. This allows design engineers and system integrators more project design options without sacrificing accuracy and zero-backlash. The new 32 mm design can be used in projects requiring a 40 mm Roller Pinion in past designs, allowing for a more compact design in applications that are limited by space.

The 40 mm Roller Pinion is designed to handle higher torque loads accurately while maintaining zero-backlash. The 200 percent increase in torque capacity maintains the same inertia as the previous design. Nexen has added additional mounting holes to the corresponding rack to handle the increase in torque of the 40 mm Roller Pinion.

“Our new Roller Pinion design allows customers to design systems that perform in the most demanding applications, no matter the length, speed, or geometry,” says Dave Hein, Vice President of Engineering. “Nexen’s new Pinion design will allow integrators to design systems that work in the most demanding designs.”

Nexen engineers and manufactures advanced motion control components for a wide variety of industrial applications. Headquartered in the USA and with its European office based in Belgium, Nexen supplies products to customers through a global network of local distributors and representatives.

More information www.nexengroup.com/linear-motion-control/roller-pinion-racks