Trio’s new Motion-PLC combines motion and logic to reduce cost and complexity of machine design

Trio Motion Technology has launched Motion-PLC, a new class of machine controller that combines motion, robotics, and logic. Motion-PLC provides Trio’s advanced motion control performance with the functionality and simplicity of a PLC to reduce the cost and complexity of machine design. The new controller combines multi-axis motion control and IEC language programming with Trio’s new MS I/O system for flexible I/O expansion. The first appearance of Motion-PLC is taking place at the SPS exhibition, Hall 1-Stand 360, 12-14 November 2024.

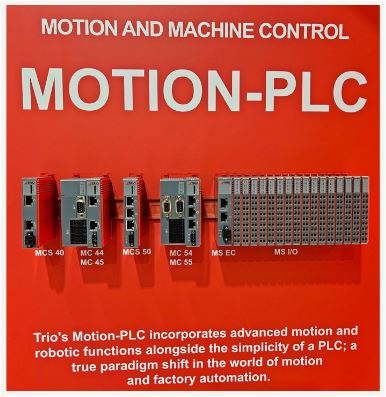

Motion-PLC is available in six models to control a range of stand-alone machines, from two to 16 axes, including robotics integration. The Motion-PLC range is for applications that need motion control and machine logic, such as gantries, packaging, and glue laying. To achieve a complete machine automation solution, control engineers can integrate Trio drives, motors, HMI, and SCARA robots, as well as Modbus TCP, PROFINET, and Ethernet/IP devices.

All Motion-PLC models include Trio’s new MS I/O system, providing compact and robust I/O expansion through a slice interface. MS I/O slices connect directly to all Motion-PLC controllers, allowing up to 16 I/O slices that combine digital and analogue inputs and outputs. The MS I/O system can be extended further with Trio’s MSEC EtherCAT coupler, allowing additional banks of MS I/O to be connected via EtherCAT.

Motion-PLC performs motion and logic control in parallel thanks to a multi-tasking operating system. This optimises machine control performance by improving data sharing between applications and removing latency of fieldbus communications. Combining motion and logic functions within a single controller also minimises the requirement for hardware and cabling, reducing cost and footprint while improving reliability.

The controller’s motion capability is built on Trio’s motion-first automation platform, Motion-iX. Motion-iX includes a variety of pre-programmed motion features, from simple point-to-point motion through to complex kinematics and robot control. Motion-PLC also includes a PLCopen motion library, and motion can be programmed in familiar PLC languages based on the IEC 61131-3 standard.

Motion-PLC achieves extensive device integration and control with an EtherCAT port, supporting up to 96 EtherCAT devices. Motion-PLC also offers up to two Ethernet ports supported by an Ethernet switch, enabling application programming plus HMI and PLC protocol support via Modbus TCP, PROFINET IO, and Ethernet/IP. Application development and device integration is managed through Trio’s license-free Motion Perfect software, a single tool for programming and diagnostics.

Motion-PLC removes the footprint required for a separate motion controller or PLC and has also been designed for minimal dimensions. The controller modules measure from just 100mm high, 23mm wide, and 75mm deep, while I/O slices are just 12mm wide. The controllers are DIN rail-mounted, and the I/O slices feature forward insertion for easy access, and their connections enable easy wiring with spring clamp connectors.

“Combining motion coordination with the functionality and simplicity of a PLC, Trio’s Motion-PLC is a true paradigm shift in the world of motion and factory automation,” says Trio’s President, Tom Alexander. “Based on Trio’s advanced motion platform, Motion-PLC can increase machine performance, but as it replaces the need for a separate motion controller or PLC, this single controller can improve machine reliability and enhance design simplicity, while reducing cost.”