Is rapid prototyping the key to drastically reducing product development cycles and costs?

What is certain is that this approach enables companies to take their products from concept to production in record time. By using modern technologies such as 3D printing, CNC machining, injection moulding, and other processes, manufacturing companies and mechanical engineers can create functional prototypes in a matter of days. This significantly speeds up the design and development process as engineers can quickly make iterative improvements.

The direct impact on product development cycles is obvious – the ability to create physical prototypes in a short space of time allows companies to respond more quickly to market changes and customer demands.

Furthermore, rapid prototyping goes hand in hand with significant cost savings. Early identification of design flaws and the ability to perform multiple iterations cost-effectively significantly reduce the overall cost of product development. Errors that are only discovered in later phases are not only more expensive to rectify but can also significantly delay the market launch.

In the dynamic industrial market conditions of 2025, adaptability is paramount for product-to-market success.

Rapid prototyping enables companies to react flexibly to new requirements and trends by adapting prototypes quickly and efficiently. The ability to create functional models in the shortest possible time enables manufacturing companies and mechanical engineers to respond to current market requirements and develop innovative solutions.

Especially in a challenging 2025, where the technology landscape is undergoing major changes, the ability to adapt quickly will become a competitive advantage. Engineers who can adapt their designs quickly and effectively to change will come out on top. Rapid prototyping is therefore not just a tool for product development; it is the key to succeeding in an ever-changing industrial world.

How does on-demand manufacturing make it so easy for engineers to create prototypes?

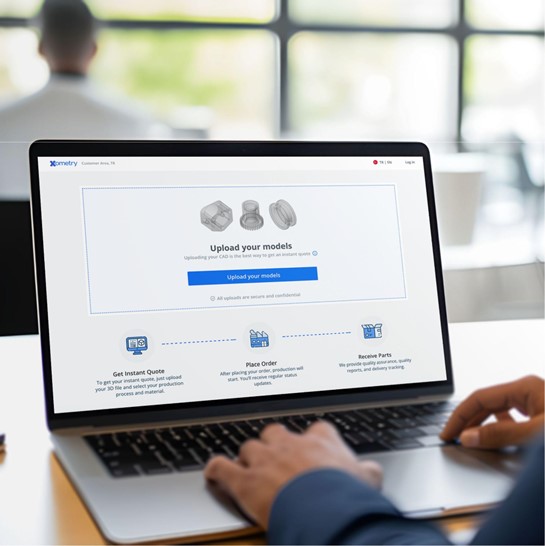

In the world of rapid prototyping, manufacturing companies, and engineers often face a variety of obstacles. On-demand manufacturing platforms significantly streamline prototyping by offering instant quotes, access to diverse manufacturing technologies, and streamlined communication, all within a single platform. This eliminates the need for lengthy supplier searches and negotiations, reduces lead times, and facilitates rapid design iterations, allowing engineers to quickly test and refine their designs, ultimately accelerating product development and time-to-market.

As the leading platform for on-demand manufacturing, Xometry offers several solutions to support engineers overcoming prototyping challenges:

● Wide range of materials: Xometry offers a wide range of materials, from plastics to metals, to fulfill even the most demanding requirements.

● Complex geometries and attention to detail: Using state-of-the-art technologies such as 3D printing and CNC machining, Xometry masters the realisation of the most complex designs and finest details with precision.

● Precision and tolerances: Xometry attaches particular importance to high precision and tight tolerances to meet the highest quality standards.

● Cost efficiency and transparent budget planning: Transparent pricing and the choice of different materials and manufacturing processes ensure cost efficiency and budget control.

● Seamless integration into existing processes: Xometry enables smooth integration of rapid prototyping into existing manufacturing processes for a seamless connection of prototype development and mass production.

● Speed and agility through express services: With express 3D printing, CNC machining, and other processes, Xometry enables rapid responses to new requirements.

In 2025, rapid prototyping will emerge as a critical enabler for innovation in modern product development. By facilitating early design iteration, reducing development time, and fostering collaboration, rapid prototyping empowers engineers to bring innovative products to market faster and more efficiently.

With Xometry as a partner, engineers can seamlessly leverage the power of rapid prototyping, ensuring access to a wide range of manufacturing technologies, streamlined processes, and the highest quality standards. This collaborative approach accelerates the journey from concept to product commercialisation, ultimately driving success in today’s competitive industrial landscape.

More about Xometry