Precision sensor supplier Micro-Epsilon has extended its combiSENSOR range with a sensor that enables non-contact one-sided thickness measurement of battery electrode coatings – to micrometer accuracy.

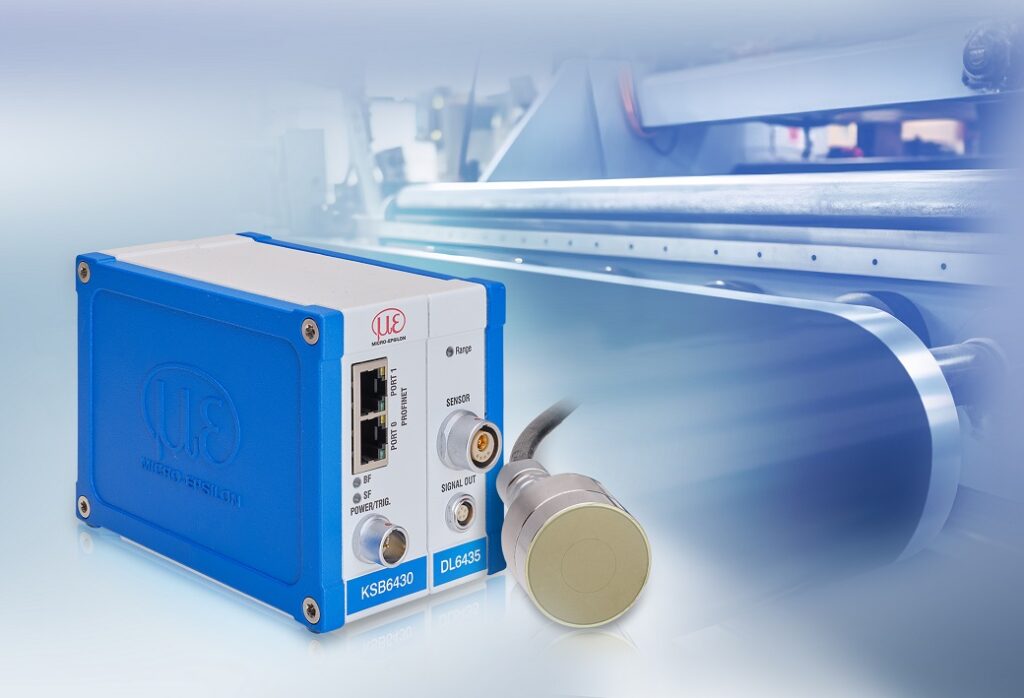

The new combiSENSOR KSB6430 combines an eddy current sensor with a capacitive displacement sensor in a single housing. This unique sensor concept enables high precision one-sided thickness measurements of battery coatings transported over chrome coated steel roller. Due to its robust design and high accuracy, the sensor is suitable for inline thickness measurements in battery film coating processes.

Stable high resolution measurements

The combiSENSOR range combines two non-contact displacement measuring principles: eddy current and capacitive, which together enable high precision one-sided thickness measurements of electrically non-conductive materials. Connected to the sensor via a cable, the combiSENSOR controller processes and calculates the signals in order to output these via digital interfaces. Calculation of the two sensor signals compensates for any mechanical changes to the target object/material, such as thermal expansion, deflections or eccentricity. Due to the redundancy of this combined sensor measuring principle, the measured thickness value remains unaffected by any changes in the measurement set up. Due to the high temperature stability of the combiSENSOR, the system provides high measurement accuracy even in fluctuating temperatures. The sensor operates within a temperature range of -10°C to +180°C.

Measuring principle

The design of the eddy current measurement coil and the capacitive measurement electrodes is concentric. Both sensors measure against the same spot. The signal of the capacitive displacement sensor is a function of the working distance, the thickness of the insulator and the dielectric constant of the insulator material. At the same time, the eddy current displacement sensor measures the distance to the ground electrode (e.g. metal roller positioned behind the film). In particular with this new combination sensor the Eddy Current element is specially calibrated for accurate distance measurement on the chrome coated rollers. The controller outputs both signals as well as the difference between the capacitive sensor and eddy current sensor. Also, the dielectric constant can be calculated with known thickness and working distance.

An intuitive web interface simplifies set up and configuration of the sensor. The controller also features digital Ethernet/IP, EtherCAT and Profinet interface options for easy integration into the user’s own production control environment.

The working range of the combiSENSOR KSB6430 is between 2 mm and 5 mm. The target thickness can be from 5 µm to max. 3 mm. Resolution of the system is 0.02 µm. Measuring speed is up to 1kHz.

For more information on the combiSENSOR KSB6430, please visit www.micro-epsilon.co.uk