3D inspection systems can visualise surfaces down to the smallest detail. In the automotive industry, for example, the smallest paint defects or inclusions in the paint result in costly reworking. Inspection systems are now available that detect defects quickly and reliably, thereby reducing costs, says Glenn Wedgbrow, Business Development Manager at Micro-Epsilon UK.

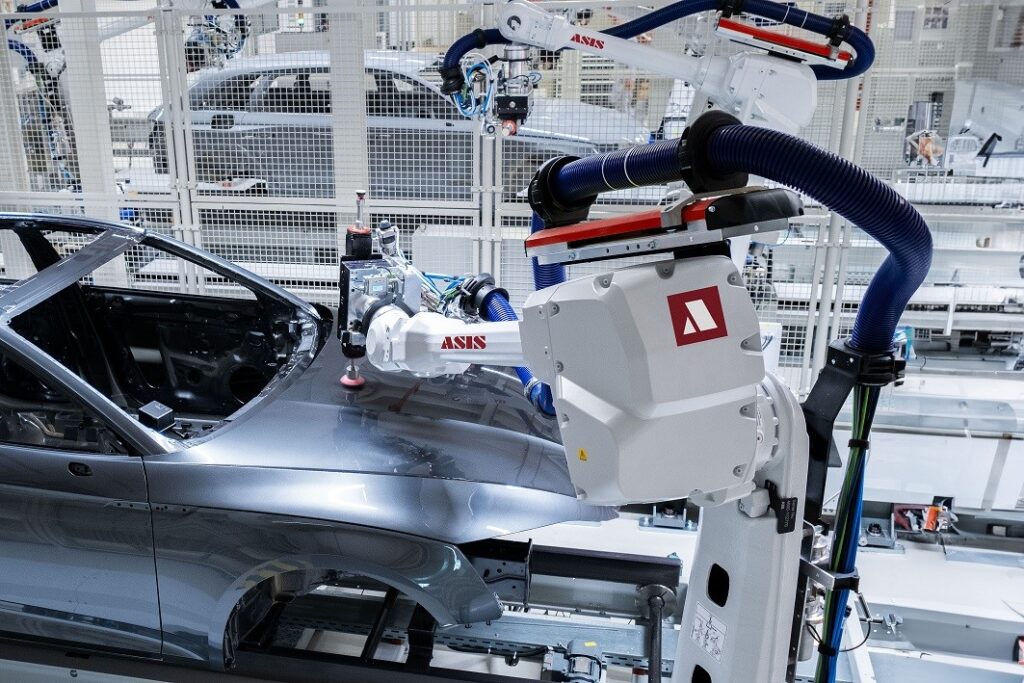

Micro-Epsilon has developed the reflectCONTROL Automotive sensor series, which is based on the measuring principle of deflectometry and is attached to a robot. (Image: Micro-Epsilon Messtechnik).

An increasing number of industrial applications require reflective surfaces to be recognised and measured. For example, in electronics manufacturing, smartphone production and in the automotive industry when producing mirrors or checking for paint defects on finished car bodies. In order to detect a fault or defect on these surfaces, OEMs require high precision measuring systems that detect deviations in the surface structure to sub-micrometer accuracies.

High precision surface scan using deflectometry

For all these fields of application, Micro-Epsilon has developed the reflectCONTROL sensor series, which is based on the deflectometry measuring principle. Here, the sensor displays a sinusoidal striped pattern via a monitor, which is reflected into the sensor’s cameras via the surface of the object being measured, for example, a car body. The resulting phase images can be used to calculate ‘kernel’ images based on the measured variables of base intensity, amplitude and curvature. Deviations on the surface are detected, processed by the software and displayed in the reflectivity and curvature images.

High resolution measuring system

The reflectCONTROL Automotive measurement system from Micro-Epsilon (also known as PSS 8005-D) has a measurement area of 367.5 mm x 823.4 mm. The sensors measure the smallest of defects at a resolution of 185 µm and operate with a measurement data acquisition time of 400 ms. The supply voltage is 24 V DC with a power consumption of less than 200 W. This high precision, high resolution benefits leading vehicle manufacturers in paint defect inspection. In the past, these companies relied on light tunnels where skilled workers would use fixed lighting systems and cameras to detect defects in the paintwork. Alternatively, systems whereby the car body would move past static sensors on a conveyor belt were also used to detect defects. However, both options are very error-prone for different reasons.

In the past, car manufacturers normally relied on light tunnels for paint defect inspection, in which skilled workers attempted to detect defects in the paint under fixed lighting systems and with the help of cameras. (Image: AdobeStock).

Shorter cycle times

This is why car manufacturers now rely on measuring systems such as reflectCONTROL, where the vehicle chassis is brought into a fixed position. The sensors are attached to robotic arms and move across the bodywork. Micro-Epsilon chose this method because it achieves the lowest error rate and the required cycle times – the time that elapses between the inspection of two vehicles – can be met.

Two to four robot arms, each with an integrated sensor, work at each inspection station – allowing the entire chassis to be measured. For very short cycle times, two stations with four robots each have proved successful – but Micro-Epsilon can offer solutions for all desired cycle times.

In order to accelerate and decelerate the robot arm sufficiently, it was necessary to keep the total weight of a sensor below 50 kg, which Micro-Epsilon achieved using a carbon housing. This also increases the robustness of the overall system and protects the robot arm, which further extends its service life.

Defect detection and automatic processing

With light tunnels, car manufacturers achieved a defect coverage of around 60% in the past meaning around 40% of defects were left undetected! With reflectCONTROL, fault coverage of almost 100% is now possible. This high fault coverage is due to outstanding defect detection and automatic processing. First, the vehicle is measured from one measuring position to the next and any defects found are projected back onto the vehicle surface. A defect can be localised at +/- 3 mm on the vehicle surface. 3D features such as height, depth and volume are added to each defect using 3D reconstruction, which is unique on the market. All collected data is saved in an XML file and so is available to the vehicle manufacturer at any time.

Once the defect has been detected and localised, automatic processing can begin, which Micro-Epsilon implements together with its partner companies ASIS and Virtek Vision. This is carried out using additional robots with active force control, each equipped with a dual-mounted sanding and polishing head. A robot first grinds off the defect and then polishes it. Used sanding sheets and polishing sponges are removed at changing stations and new ones are picked up automatically. New polishing sponges are automatically prepared with polishing agent. The polishing agent is supplied directly to the robot using a clever cartridge principle. Using a laser marking system from Virtek Vision, the defect is then marked as machined without contact by projecting light onto the body. If required, additional defects can also be displayed via the projection, which must be reworked manually. The system knows at all times which robot is currently processing which points or which defects have already been processed.

The most important prerequisite for automatic processing is the detailed database that Micro-Epsilon can provide with reflectCONTROL. This enables OEMs to optimise their production, identify error chains and intervene at an early stage if errors occur. This saves OEMs time and costs in production.

Extensive database

Another important innovation is the classification of data. This can be used to automate the processing of errors. Classification means recognising the type of defect, for example, whether it’s a crater, inclusion or defect from the sub-surface. The customer also has access to 3D data so they can access the exact dimensions of the defect at any time and initiate extensive analyses. As all data can be transferred to the company’s internal Q-System at any time, alarm functions can be set up and faults communicated at the appropriate point.

System learns automatically

More data can be derived from the 3D image and used to determine a wide range of variables. The system can also independently define new defect classes. Due to the large database, the system can also be used for audits. The labelled data is also used to train the underlying AI algorithms.

All data is available to the OEM in a file and can be read into the standard higher-level Q systems. This means that the data can also be visualised using established tools. The system learns from all the data it collects and therefore becomes increasingly ‘intelligent’. This saves the OEM time when working through errors, and the data can also be used to set up early warning systems to detect and eliminate error chains at an early stage. For example, warning thresholds can be created when certain numbers of defects are exceeded. In addition, heat maps can be used to find error hotspots and draw conclusions about certain upstream processes.

Appearance measurement to evaluate surface structure

In addition to automatic processing with partner companies, Micro-Epsilon can perform an appearance evaluation that enables a structural evaluation of the surface. The existing paint structure is broken down into its spectral components. The components are summarised in different frequency ranges, for example, short or long wave, i.e. which short and long waves are contained in the structure of the surface, as no surface is perfectly smooth.

It is important for car manufacturers to maintain certain appearance values on a car body. Automated cells, end-of-line cells or aqua cells are normally used for this purpose. A vehicle is inserted into this and viewed by a robot with a scanner. The robot moves to the various positions and measures the appearance directly over the surface. This takes around 20 minutes in total – so a maximum of three vehicles can be measured per hour.

With the system from Micro-Epsilon, the appearance can be evaluated on the basis of the existing images without additional hardware. This saves time and costs for the OEM. In addition, any number of measurement positions can be defined, which basically corresponds to a full-surface appearance measurement. The number of vehicles is also not limited. The evaluation can also be output for each body. This enables the OEM to recognise trends and set and issue alarm signals – before major damage occurs.

Recognise and avoid defects

With reflectCONTROL, defects in reflective surfaces can be detected and classified almost 100%. The system is superior to conventional light tunnels and static systems, particularly in the field of paint defect inspection in automotive production. Due to the large database, manufacturers of automatic processing systems are able to assign the correct processing recipes to the defects. This reduces unnecessary defect handling and therefore saves the OEM resources and costs.

Micro-Epsilon offers reflectCONTROL as a complete system from error detection to the analysis of 3D data via the database. ReflectCONTROL is developed and manufactured at Micro-Epsilon sites in Germany and Austria. Micro-Epsilon can implement reflectCONTROL at production sites worldwide – due to its international subsidiaries.

For more information on reflectCONTROL, please visit www.micro-epsilon.co.uk