With fast delivery and customisation, Apex Dynamics has unveiled its new range of zero backlash precision couplings, designed to take the headache out of shaft-to-shaft connections.

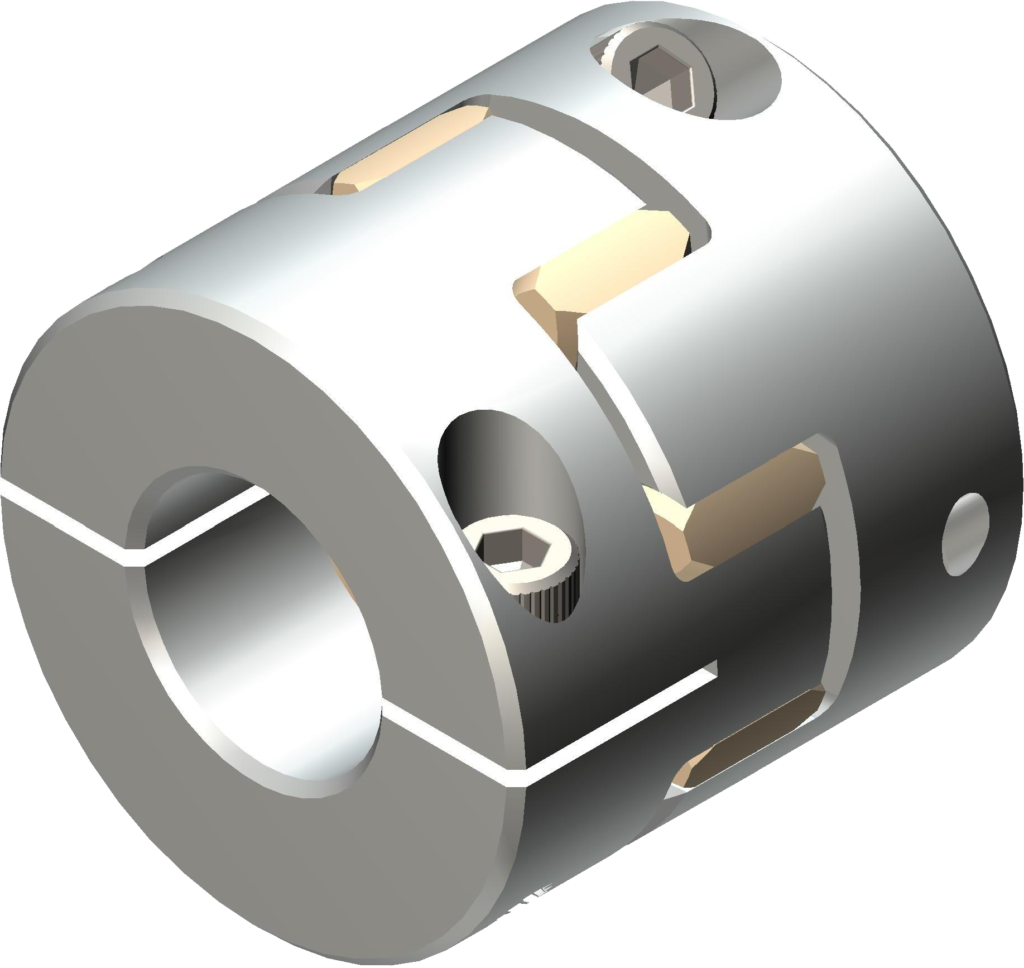

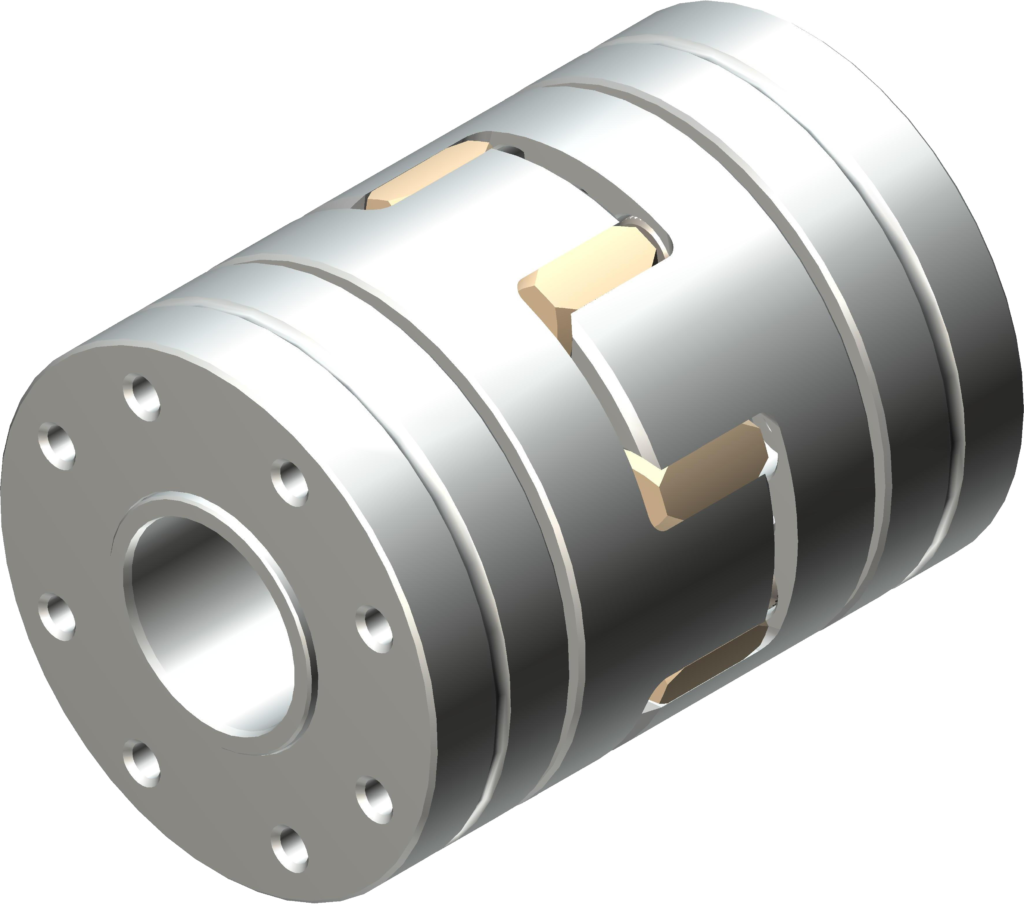

Apex Dynamics has launched its latest product range and this time it is the company’s first ever series of couplings. The Zero Backlash Precision Couplings for shaft-to-shaft connections come in elastomer and disc variants, with a wide variety of input and output configurations.

Each coupling is machined to order, ensuring it meets every customer’s precise application needs, with delivery guaranteed in just 2-3 weeks. Designed to meet the highest standards of performance and adaptability, the zero backlash precision couplings expand Apex Dynamics UK’s portfolio beyond servo gearboxes and rack and pinion systems.

Meeting customer demand for high quality, custom machined couplings.

According to Apex Dynamics, the new elastomer and disc couplings are a direct response to customer demand. Many of the companies purchasing its gearboxes have complained about not being able to find the right size, quality and range of couplings to meet their needs, or that can be delivered fast.

Apex Dynamics couplings are made to the company’s high production standards. Each coupling is bored to order and configured by specialists, meeting customers’ exact specifications and ensuring the correct fit every time. The new range has been designed with easy axial installation in mind, making setup quick and efficient.

Elastomer and Disc variants to meet individual requirements.

Both the elastomer and disc precision couplings from Apex Dynamics provide high quality zero backlash connection. Each range delivers exceptional torsional rigidity, high-speed capability and shock absorption for high-gain motors.

The precision disc couplings comprise a torsionally rigid laminate disc that allows for angular and axial misalignment properties between meeting points, with bore capacity up to 80 mm. They offer flexibility with backlash free operation, making them perfect for encoders, direct-drive, high-speed, and high-torque applications. With an aluminium alloy plain or keyed hub and size range from 05-61, the Apex Dynamics couplings come in single or double disc variants and have a nominal torque range to 2000 Nm and peak torque range to 3000 Nm.

Disc couplings can also be combined with universal joints (U-joints) or extension shafts to manage significant misalignment more effectively.

The flexible, cost-effective elastomer couplings, with high vibration damping come in a variety of I/O and elastomer material options. Capable of absorbing shocks to accommodate misalignment and transmit torque, they have peak torque range to 4500 Nm, a variety of sizes from 7-90 and bore capacity up to 110 mm. Ideal for servo/stepper motors and spindle drives, the elastomer couplings can withstand temperatures of -50 to +150, depending on the variant.

Mike Gulliford, Managing Director of Apex Dynamics UK, says, “The addition of couplings to our portfolio of products perfectly complements our gearboxes and rack and pinion sets, as well as solving a key headache for many of our customers.

“We are as confident about the quality of our new precision couplings range as we are about all Apex Dynamics products and are offering our industry-leading five-year guarantee. Get in touch today and let us help you find the perfect coupling for your project.”