Steyr, Austria, October 2023. NKE Austria GmbH presents its bearings for railway applications. The bearings are used in traction motors and locomotive gearboxes as well as in railcars, trams and underground trains.

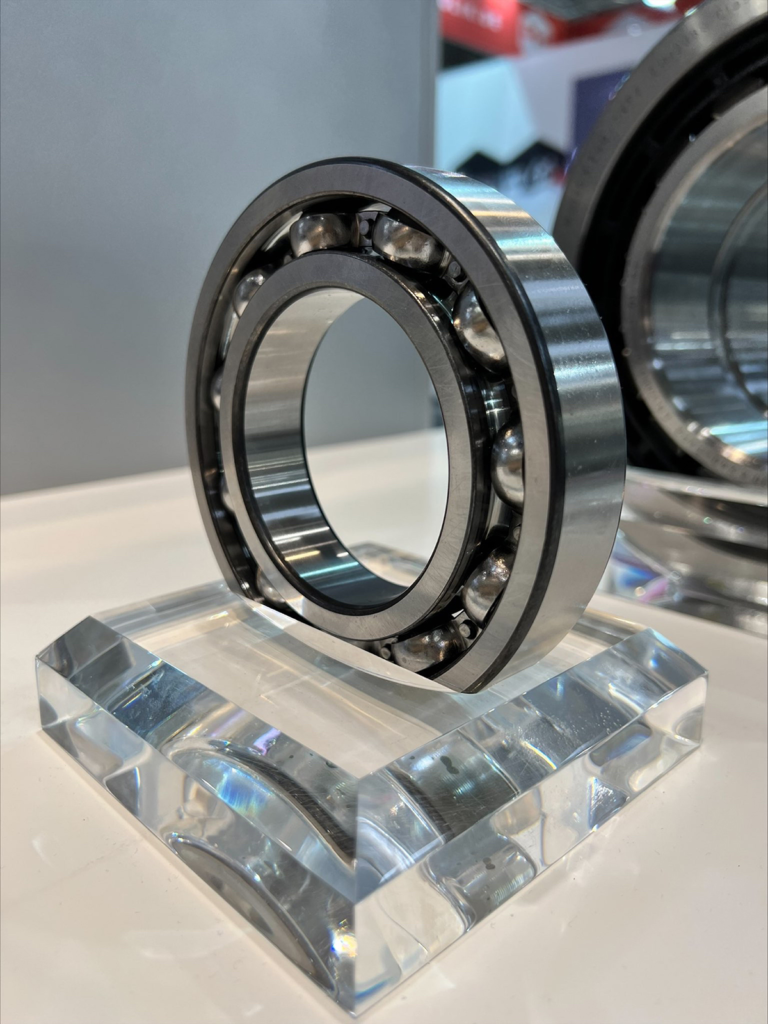

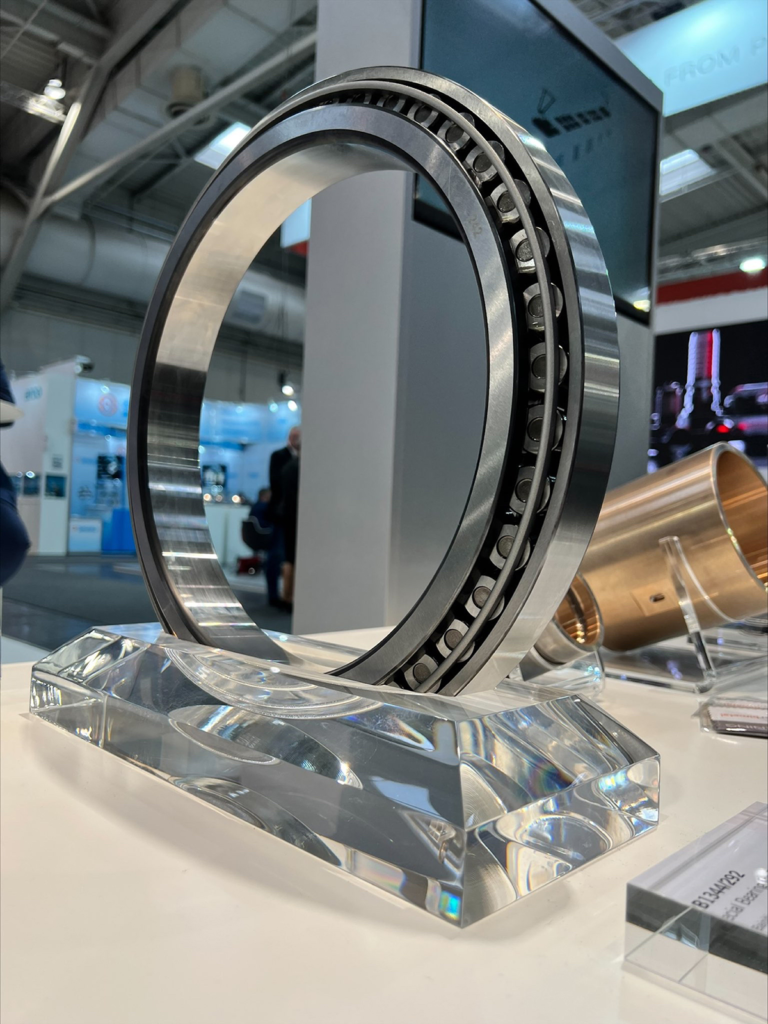

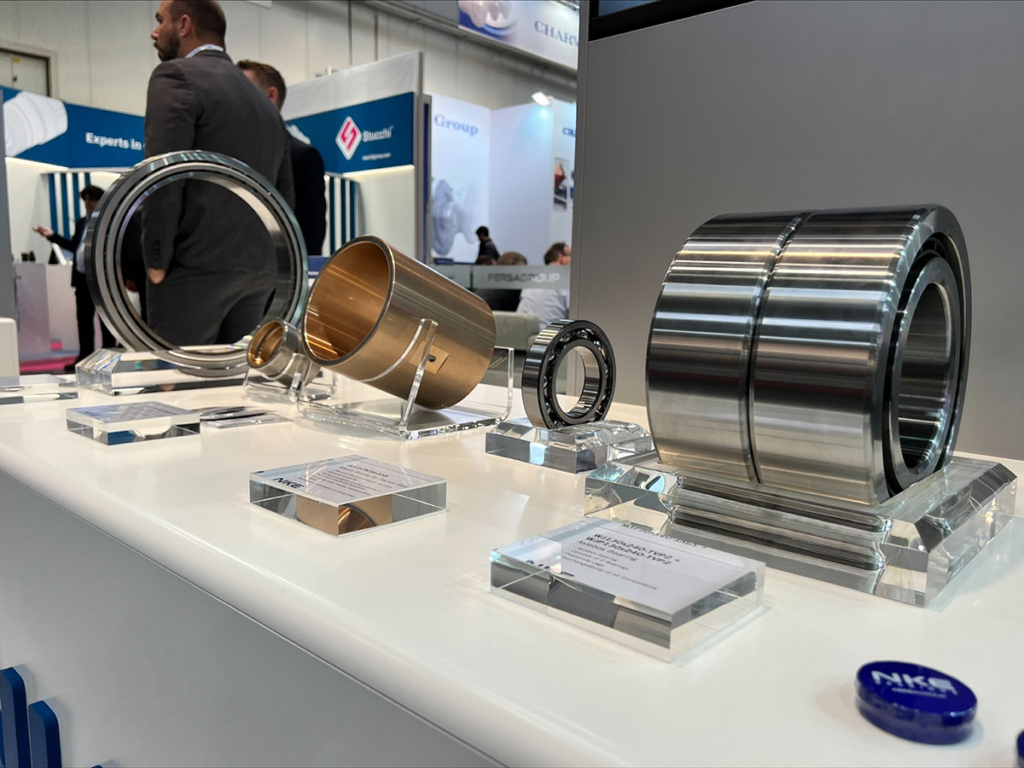

When designing a rail vehicle, it is essential to consider factors such as loads, speeds, torques and installation space. These factors must be considered also when selecting the power transmission components. Bearings for gearboxes operate at high speeds and under high loads. They must be able to withstand shocks, vibration and extreme temperatures. Bearings for traction motors are required to have long service life. The most commonly used bearing types in rail vehicle gearboxes are cylindrical roller bearings, tapered roller bearings, angular contact ball bearings, four point contact ball bearings and deep groove ball bearings. In traction motors, most typical are cylindrical roller bearings and deep groove ball bearings. Often these bearing types are electrically insulated, with a corresponding coating on the outer or inner ring. For particularly demanding applications, hybrid variants are available. The rolling elements of hybrid bearings are made from heavy duty silicon nitride (Si3N4), an extremely hard wearing ceramic. Bearings for gearboxes and traction motors can also be customised and produced to special specifications, for example higher thermal resistance or more stringent tolerance ranges.

“Our design of electrically insulated cylindrical roller bearings and deep groove ball bearings includes an oxide ceramic coating,” says Klaus Grissenberger, application engineer with NKE in Steyr, Austria. “This offers simple, effective protection against bearing damage from current passing through the bearing.” The insulation significantly reduces the risk of damaged raceways and premature ageing of the lubricant, and has a dielectric strength of 1000 V and 3000 V with DC or AC voltage respectively. The electrically insulated bearings have the same dimensions and technical properties as conventional bearings, so they are easily replaceable. Versions available are bearings with insulation on the outer ring (SQ77) or on the inner ring (SQ77E).

Hybrid deep groove ball bearings from NKE are noted for the extremely high degree of protection they offer against damaging bearing currents, prolonged service life – also of the lubricant -, exceptionally quiet running, and low friction and associated losses. “Our hybrid deep groove ball and cylindrical bearings represent the premium solution for the prevention of current-induced bearing damage,” says Grissenberger. “This is achieved due to the excellent material properties of the ceramic balls, for example outstanding compressive strength and rigidity, low density, and of course the highest possible electrical resistance.”

When developing bearing solutions for railway applications, NKE’s Applications Engineering department works closely with customers, which include well-known OEM manufacturers, railway operators and service providers. All bearings undergo rigorous, documented quality control procedures. Apart from product development, NKE also offers technical support in the selection of bearings, dimensioning and condition assessment, and conducts training courses. Since 2005, the Austrian bearing manufacturer has delivered over 40,000 bearings for rail vehicles.

NKE at railway engineering trade shows:

Rail Live 2023,29 November to 1 December 2023, IFEMA Madrid, Spain: Booth B071

InnoTrans 2024, 24 to 27 September 2024, Messe Berlin, Germany

Photos:

Company information:

NKE Austria GmbH is a manufacturer of high-quality rolling bearings with headquarters in Steyr. The company was founded in 1996 by senior employees of the former Steyr Wälzlager. In 2016, the Spanish bearing manufacturer Fersa Bearings, which specializes in the automotive sector, acquired 49 percent of NKE and completed the acquisition at the end of 2018 with 100 percent. NKE produces standard and special bearings for all industrial applications. Engineering, product development, manufacturing and final machining of components, assembly, quality assurance, logistics, sales and marketing are concentrated at the Steyr site. The Steyr plant is certified to ISO 9001, ISO 14001 and ISO 45001. A comprehensive range of standard bearings is available from stock or produced with short lead times. Solutions are also developed and manufactured for special requirements. In addition to product development and application engineering, NKE offers comprehensive technical services, consulting, documentation and training. NKE bearings are distributed through 12 sales offices and 240 trading partners in 80 countries.