The current demand for skilled engineers across all sectors of UK industry is well documented and something constantly mentioned in the general, specific engineering and manufacturing media. It was one of the key topics discussed at the recent Farnborough International Airshow (FIA) showcasing an industry which generates income to the UK economy estimated to be £13bn per annum and predicted to grow exponentially. It was also an ideal platform for the new UK government to announce ‘Skills England’, a body that aims to provide valuable opportunities for ambitious young individuals, particularly those interested in apprenticeships. With the world of work evolving faster than ever, it’s never been more important to secure and nurture the best new talent in engineering, so the availability of apprenticeship opportunities in crucial.

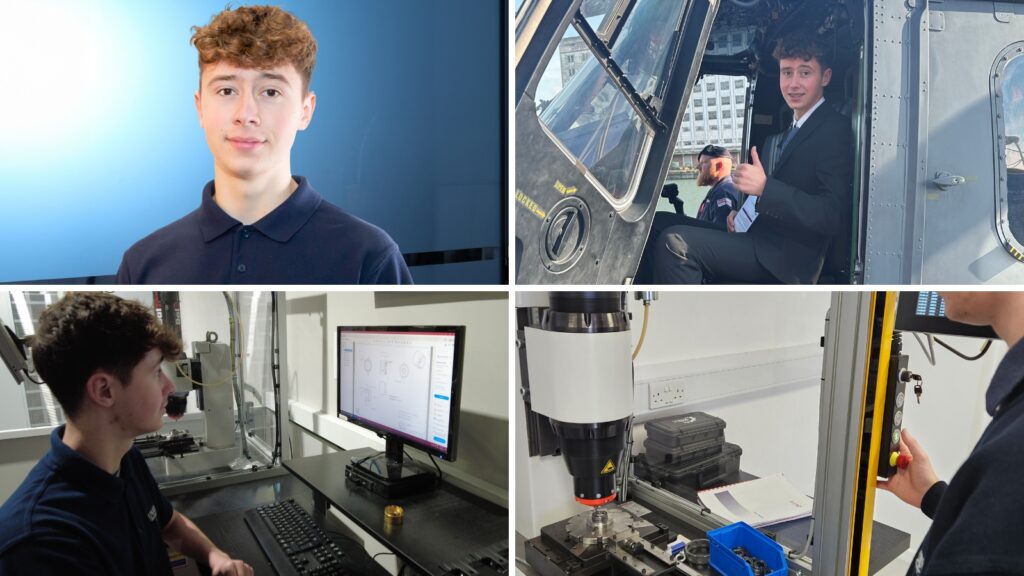

A good example of where apprenticeship opportunities can be effective is at precision bearing and tooling specialists CARTER MANUFACTURING who are delighted to share the experience and success of one of their Apprentice Engineers, 19 year old Jake Hopgood. Jake attended Abingdon and Witney College studying for a ‘Level 2 Engineering Diploma’ one day a week, along with his hands-on, practical experience 4 days a week at Carter. He recently completed his 2 year apprenticeship at Carter and we caught up with Jake to talk about his role and experience at Carter, perhaps helping to inspire others hoping for a career in engineering.

What was the main inspiration for Jake to pursue a career in Engineering?

From a young age I actually wanted to be a builder following in the footsteps of my father, although he always used to tell me, it’s not a great job and I think you could be doing something better! Another family influencer was Jake’s grandfather who told Jake about engineering and told him to look it up and find out more about what engineers actually do. “Ever since then engineering is all I wanted to do.”

No other family members are involved in engineering although Jake added that a few of his friends are engineer apprentices at other companies.

What specific industry sectors was Jake interested in?

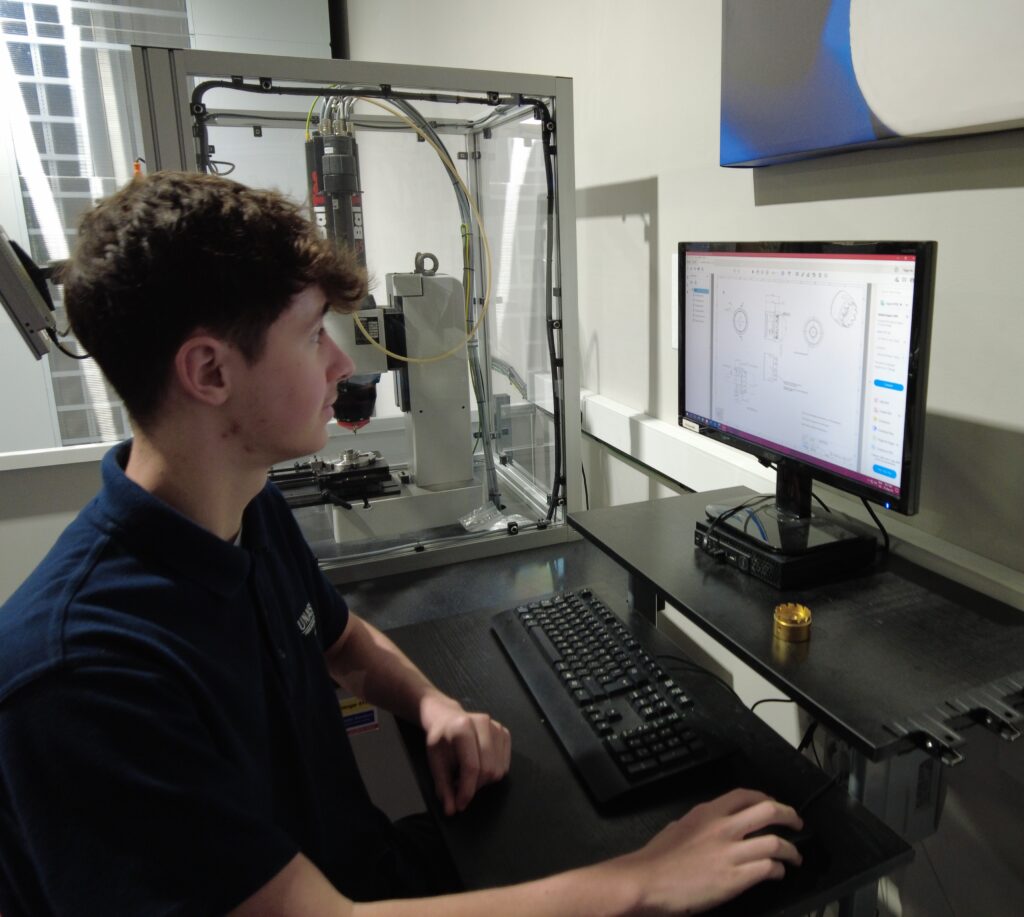

“The sectors I’m most interested in are machining, assembly and inspection, mainly because I really enjoy using the CMM machine”.

What role, job function did Jake fulfil?

“As an Apprentice Engineer at a precision bearing specialist company I fulfilled quite a few things, for example; bearing and tooling assembly, machine operating, a little bit of SolidWorks/CAD, MD coating, programming and operating a riveting machine. Also, programming and operating the CMM machine, cryogenic testing bearings using Liquid Nitrogen and using the RIC rig to find out the radial internal clearance of bearings. In addition, fire warden and health & safety training”. Most importantly, Jake’s experience included a first-hand insight into Carter’s acknowledged specialist expertise as a leading precision bearing and tooling supplier too many of the UK’s leading high-technology companies. This meant he needed to be involved in assembling hybrid bearings for cryogenic applications, light weight slewing bearings for the defence sector, titanium bearings for highly competitive yacht racing and aluminium thrust bearings for the medical sector.

Why has your time spent at Carter been a success story?

Jake comments, “I wanted to share my positive experience as an apprentice at Carter. I feel like it’s been a great success story because I joined a specialist bearing and tooling company knowing next to nothing and in the last 2 years I have learnt so much. I now know how to do things I never imagined I would know”.

What next for Jake?

Jake concluded, “Hopefully, I can go onto bigger and better things and keep building myself up, step-by-step and achieve great things in engineering”.

More information – What is an engineering and manufacturing apprenticeship?

An apprenticeship in engineering is a hands-on, work-based route into your chosen career. You will gain the qualifications and skills to become an engineer or manufacturer, while earning a salary and not paying tuition fees.

You could be building smart cities, working in robotics, or working with pyrotechnics on film sets.

More at: https://www.ucas.com/explore/industry-guides/engineering-and-manufacturing