In recent years, additive manufacturing (AM), or “3D printing”, has quickly opened up new production frontiers. Structures once regarded as being impossible to fabricate with traditional machining techniques have become commonplace. Moreover, the original delicate parts formed by earlier AM technologies, suitable only for prototyping and laboratories, have now given way to methods that provide actual production parts. These are commonly used in applications that can be as demanding as jet engine turbine blades. While material science has led the way in these advances, high precision motion control and the ability to combine this with all other machine functions has delivered significant competitive advantage for one AM machine manufacturer by adopting CC-Link IE TSN.

Now that AM has moved out of the prototyping lab and into mainstream production lines, it has become subject to all the same pressures as its subtractive manufacturing cousin. Parts must meet stringent specifications and quality standards while being produced to meet aggressive schedules and cost targets. As a result, manufacturers of AM systems have been under pressure to produce machines that continue to raise the bar on customer expectations as market forces intensify.

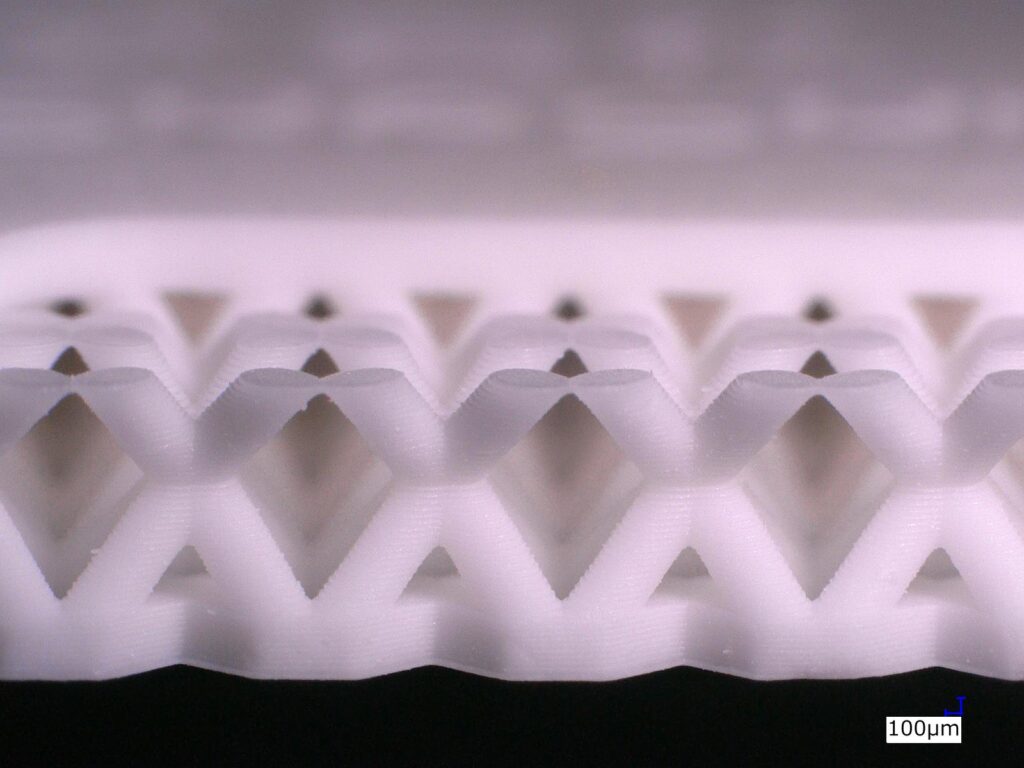

Shashin Kagaku is a Japanese manufacturer of AM systems that form high precision parts using a ceramics-based process. Their new SZ-6000 system uses an alumina or aluminium oxide powder mixed with a resin to form a slurry that is cured under UV light. This is then used to build up parts layer by layer by using UV light to cure the photosensitive slurry into the required form. Finally, a kiln fires the parts, evaporating the resin and making them durable enough for real applications via sintering of the ceramic powder.

The SZ-6000 can manufacture relatively large-scale parts, with dimensions exceeding 600 mm square and 300 mm deep, while maintaining manufacturing tolerances on the scale of thousandths of millimetres. To do this, extremely fine motion control of a variety of rotary and linear axes in an interpolated manner is required. These also need to operate at high speed to meet the necessary productivity targets. Of course, the complete machine architecture extends beyond just the motion control aspects. Tight control of the UV digital light processing (DLP) exposure system must be closely coupled with the motion axes, while also integrating all other machine functions.

To meet these demanding requirements, Shashin Kagaku turned to CC-Link IE TSN, the world’s first open industrial Ethernet to combine gigabit bandwidth with Time-Sensitive Networking (TSN). In this application, the use of TSN technology permits disparate types of network traffic to share a single network architecture by employing IEC/IEEE standards, such as 802.1AS and Qbv. These synchronise traffic flow across the network and regulate the priority of different traffic types. By leveraging TSN along with the industry leading gigabit bandwidth of CC-Link IE TSN, Shashin Kagaku were able to realise a number of key benefits.

The convergence of different network traffic on the same architecture allowed the complex, multi axis, high precision motion control system to be run on the same network as the rest of the system I/O. This, in turn, delivered the tight integration between the motion control systems and the operation of the UV DLP exposure system. The maximum number of axes that could be handled by this system was up to 128, providing scope for even more advanced systems in the future.

Consequently, the construction of the machine could also be simplified, as less wiring was required to construct the internal systems, leading to reduced construction time. As a result, Shashin Kagaku could offer shorter delivery times, reduced system cost and a more competitive product.

The gigabit bandwidth of the network contributed to a component production time that is about ten times faster than Shashin Kagaku’s existing systems. More precisely, a minimum motion loop closure time of 125 microseconds could be achieved, allowing the company to offer a step change in productivity.

TSN’s ability to converge OT and IT traffic allowed a conventional industrial PC to be integrated into the setup without the need for dedicated hardware, further simplifying the machine and helping to reduce cost. This also provided an interface to external CAD systems in order to download designs, which can be converted into the motion programs, which control part forming.

The end result was an extremely productive AM machine that provided Shashin Kagaku a significant lead over its competition in what is already a highly competitive marketplace. More importantly, its customers also benefit from a significant increase in productivity in the form of an even more cost-effective tool.

John Browett, General Manager of CLPA Europe, commented: “We have known all along that CC-Link IE TSN was capable of delivering significant productivity benefits to end users and machine builders alike. This advanced additive manufacturing system from Shashin Kagaku shows just how.”

Web: eu.cc-link.org