Delta announces the debut of two Industrial Automation products at SPS Italia, taking place on 13-15 May 2025. Engineered for the Industry 4.0 era, the new ASDA-A3EP servo drive and the new Delta Human Machine Interface DOP-300 Series help accelerate the pace of factory automation while realising greater efficiency, agility and productivity benefits. They will both be present on Delta’s booth (5, A025) alongside its existing range of VP3000 Series Drives and MSI Motors, and the award-winning Delta D-Bot Series Collaborative Robots.

Key SPS Italia show highlights include:

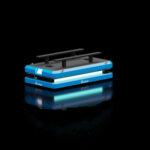

ASDA-A3EP with advanced safety:

The ASDA-A3EP is a new servo drive from Delta. Developed with feedback from end users, it is a general-purpose ‘pure servo’ drive ideal for any machine builder as it can to be integrated in an Ethercat architecture. Safety is at the heart of the ASDA-A3EP; with its external safety card, users have 12 additional safety functions activated by either digital input or Fsoe. This technological step enables the drive to be used in the most complex motion applications that require advanced safety functions. Additionally, the built in STO Sil 3 addresses the simplest safety requests.

For added performance, the ASDA-A3EP offers 400vac. It scales from 100W to 15 kw – making it suitable for most machine builders – and it also includes a built-in Ethernet interface. With high power density and top-down wiring, the ASDA-A3EP presents an effective balance between power density and industrialisation, offering customers a highly reliable solution. It provides high levels of safety, performance and reliability within a compact cabinet for added user convenience.

Delta Human Machine Interface DOP-300 Series:

Delta’s Human Machine Interface DOP-300 Series includes 7” and 10” models for different applications. Its dual-core high-speed processor supports MQTT and OPC UA protocols. The built-in Wi-Fi and 4G wireless antennas – combined with an easy-to-install wireless communication module – greatly enhance the wired and wireless networking capabilities, which facilitate ground-to-cloud connection. With an ultra-wide viewing angle, 24-bit colour display screen supplemented by a full-lamination panel design, the DOP-300 Series features enhanced visual quality and a tactile user experience. The DOP-300 Series also meets today’s smart manufacturing demands with various features – including the Delta Cloud Platform DIACloud – to build a complete and secure IIoT ecosystem with seamless connection. Delta’s web Interface Editor DIAWebDesigner offers exceptional development capabilities for customisation. It enables users to set key data, design a user-friendly interface, and monitor the data uploaded by the DOP-300 to obtain the real-time status of equipment and production lines.

VP3000 Series Drives and MSI Motors:

Delta’s VP3000 Series Drives and MSI motors are designed for energy savings and low harmonic distortion in industrial applications. For fluid industries, the VP3000 Series offers high efficiency and stability for water supply, wastewater treatment, HVAC, and utilities. With a wide power range from 0.75 to 630 kW, it can control various motor types, ensuring effective harmonic suppression and reduced energy use. Features include low harmonics with THDi (≦35%), safety functions (STO SIL3), EMC filters, high power density, and predictive maintenance for reliability.

Complementing the VP3000 Series, are high-efficiency PM synchronous reluctance MSI Motors engineered for energy savings and motion accuracy. Achieving IE5+ ultra-high efficiency, they deliver superior performance with significantly reduced energy consumption and CO2 emissions. The MSI Motors are also designed for long service life, with robust construction and minimal maintenance requirements. Compact, low noise, and easy to integrate, they suit applications like fans, water systems, and compressors. Delta’s VP3000 Series Drives and MSI Motors redefine industrial efficiency, meeting modern smart manufacturing requirements.

Delta D-Bot Series Collaborative Robots

Delta’s award-winning and versatile D-Bot Series Collaborative Robots (Cobots), are available in six models (D-Bot 6-30), and offer payload capacities ranging from 6 to 30kg and reach spans up to 1800mm. With six axes, they deliver speeds up to 200 degrees/second, making them ideal for precision tasks such as pick and place, welding, and palletizing. The integration of 24-bit encoders ensures exceptional precision, while compatibility with EtherCAT, Modbus, and CODESYS facilitates seamless integration into existing industrial environments. Designed for safety and ease of use, the D-Bot series features IP66 protection and “Reflex Safety” to ensure a secure workspace. It detects contact at lightning speed and instantly reverses movement to prevent accidents, protecting both personnel and equipment. The integration of high-end sensors and collision detection (one-finger tap) maximises safety.

The “Plug & Play” setup and intuitive programming options, including drag-and-drop, Python, ROS 1, and C++, simplify operation for users of all skill levels. A modern Graphical User Interface (GUI) with 3D visualisation and an integrated HMI panel further enhance usability. Key features include the range of D-Bot 6-30 models, high accuracy, versatile integration options, robust safety features, and simplified programming.

The D-Bot Series is engineered for rapid deployment, allowing setup in under two hours, making them ideal for dynamic production environments. With an impressive accuracy of ±0.02 mm and a payload range from 6 kg to 30 kg, the D-Bots are versatile and capable of handling a wide array of tasks, from assembling complex components to managing heavy palletizing. Designed and engineered in Europe, and built for the world, these collaborative robots are ready to meet the needs of businesses globally.

For more information about Delta’s industrial Automation, please visit: Solutions – Industrial Automation Solutions – Delta EMEA