Delta, a global leader in power management and a provider of IoT-based smart green solutions, announced its participation in SPS Italia 2024 to present its latest innovations in factory automation, including the revolutionary D-Bot Series collaborative robot portfolio, which offers models capable of handling payloads as heavy as 30 kg with reach up to 1,800 mm.

Delta D-Bot

Luca Cavagnari, Head of Sales Italy, Industrial Automation Business Group, Delta Electronics EMEA region, expressed his enthusiasm for the event, stating, “Our showcase at SPS Italia 2024, is part of Delta’s strategic initiative to empower industrial evolution with high-efficiency, high-flexibility solutions that address the growing demand for advanced automation across various industries. Moreover, we are excited to present our new collaborative robot solutions, designed to transform traditional manufacturing into intelligent, automated production lines”.

Delta D-Bot IP66

Delta’s highlights at SPS Italia include:

- D-Bot Series Collaborative Robots (Cobots): Delta’s newly launched D-Bots are tailored for quick deployment and ease of use, providing plug-and-play functionality and intuitive programming. These innovations strengthen Delta’s presence in smart factory automation, meeting the industry’s pressing needs for adaptability and efficiency. The cobot range includes models with payloads up to 30 kg and reaches up to 1,800 mm, compatible with EtherCAT, CODESYS, and Modbus, ensuring high precision in applications like pick & place, palletizing, and welding.

- IIoT Solution for Industry 4.0: Delta is enhancing its IIoT platform with three significant upgrades. The DOP HMI connects directly to DIACloud, facilitating efficient OT data sharing and remote maintenance without the need for VPNs. The DIAWeb Designer simplifies data visualization and decision-making through its user-friendly dashboard, and the AS-FFTP01 Function Card offers AS PLC users economical IIoT connectivity with an OPC UA server, MQTT client, and Node-RED dashboard integration, underscoring Delta’s dedication to enhancing connectivity and intelligence within industrial settings.

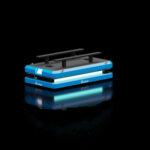

- New Industrial Panel PC: Delta introduces several new Industrial Panel PC models, available with 12-inch, 15-inch, and 19-inch capacitive touch screens. These devices, powered by processors ranging from the efficient Intel® Celeron J1900 to the robust Intel® Core i5, are designed to maximize reliability and performance. Their fanless design and IP65-rated front panel provide durability and silent operation, while a Mini PCIe slot allows for enhanced connectivity options including Wi-Fi, Bluetooth, 4G, or 5G. Equipped with a versatile 12/24 VDC power input, these Panel PCs are well-suited for challenging industrial environments.

- Advanced Automation Controllers: The AX-5 Series PLC-Based Motion Controllers are at the forefront of Delta’s motion control technology. These controllers incorporate the latest multi-core processors for rapid response and high-performance automation. Their ultra-slim design and support for major communication protocols such as EtherCAT, CANopen, PROFINET, and MQTT, make the AX-5 Series highly flexible and efficient, ideal for a broad range of industry applications.

AX-564E

PLC_AS164T

Delta invites attendees to visit Booth 5A025 at the Fiere di Parma Exhibition Centre from 28 to 30 May, to see firsthand how Delta’s advanced solutions are addressing industry challenges, enhancing productivity, and boosting operational efficiency. For more information about Delta, please visit https://www.delta-emea.com/en-GB/landing/sps-parma-2024