Providing safe material flow in the field, the new DMM4 muting module from SICK Sensor Intelligence provides safe human-material differentiation to improve protection and productivity in industrial settings.

As part of its commitment to industrial safety and access guarding, SICK Sensor Intelligence has unveiled its powerful new DMM4 muting module. The DMM4 meets a wide range of muting needs and is highly reliable, flexible and configurable to deliver enhanced industrial safety without compromising productivity.

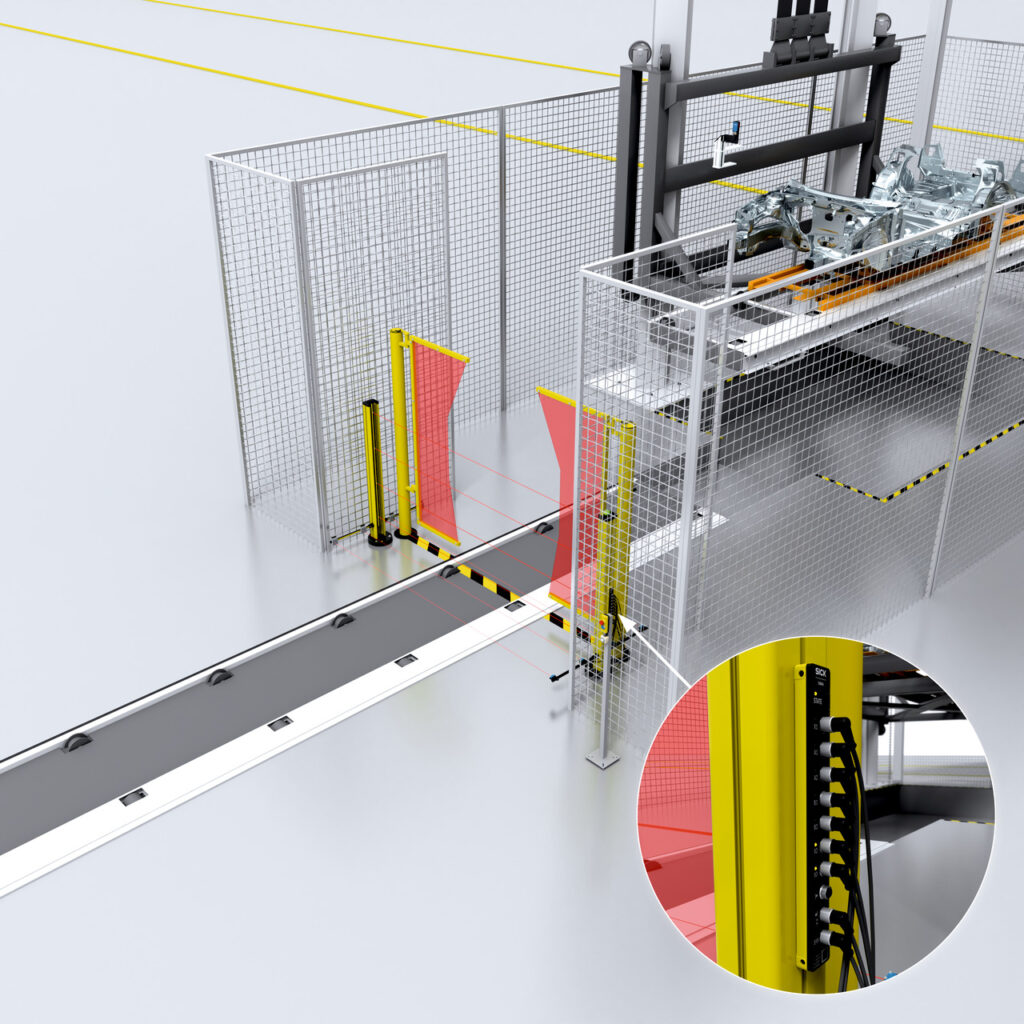

SICK is a world leader in safe access protection and innovative light curtain muting and the DMM4 extension module represents the latest evolution in its complete portfolio of solutions. It makes sure operators stay protected from hazardous machinery while materials, boxes and finished products move through smoothly. A robust, in-the-field solution with a host of new features and benefits, the DMM4 is fully compatible with SICK’s deTec safety light curtains and deTem safety light-beam sensors for seamless protection and efficiency with easy installation.

Enhanced safety and efficient material flow with the DMM4

Muting is a method that has been around a long time and has developed to become more versatile. Modern manufacturing requires safe passage of goods between production processes and this is increasingly important as production becomes more complex. A standalone muting module offers high flexibility and safety for free-flowing production and the DMM4 has a small footprint.

SICK’s DMM4 robust muting module is designed to perform in the field and can be easily integrated with all SICK deTec safety light curtains and deTem safety light-beam sensors to minimise the possibility of manipulation, while keeping workflows uninterrupted. It doesn’t require a separate cabinet as it is equipped with protection against dust and water in the field, reducing wiring and commissioning time.

The DMM4 is an innovation in entry/exit access guarding, equipped with a host of new tools, features and benefits to minimise false stops. A dedicated muting module with a high IP rating, it can be used in safety function up to PLe (ISO 13849)/SIL3 (IEC 62061) and fully supports compliance with ISO 13855, the standard covering the requirements of positioning safeguards with respect to the approach of the human body. The DMM4 is a more powerful, slimmer extension module than previous versions and SICK has released robust new support columns with micro adjustment capabilities and a built-in spirit level to complement it.

DMM4 demonstrates SICK’s rich expertise in safety light curtains

SICK has supplied safety light curtains since inventing the technology in 1946 and has a wealth of knowledge in the field. The DMM4 provides more features than basic muting options and better flexibility at a lower cost than muting using a safety PLC or safety controller. The free and intuitive SICK Safety Designer software enables easy and flexible configuration of muting parameters, smart functions and operating mode, with key features including mode switch to store different configurations, smart restart interlock, and access to a full diagnostics and error history.

Applications for the DMM4 muting module range from logistics (e.g. muting for AGVs, electric forklifts or AMRs), to manufacturing (from large automotive parts to small consumer goods, food & beverage, and pharma).

Why is the DMM4 is the best option for safety light curtain muting?

Muting – or the temporary automatic suspension of a safety function by way of safety-related parts of the control system – aims to achieve continuous, efficient material flows, while protecting people from hazards. In the case of a safety light curtain, sensors and process signals can safely identify materials to initiate a mute and allow the product to pass through without stopping the system. The DMM4 muting module meets industry standards for safe material flow through electro-sensitive protective equipment (ESPE), accurately and reliably differentiating between material and a person to provide safe conditions.

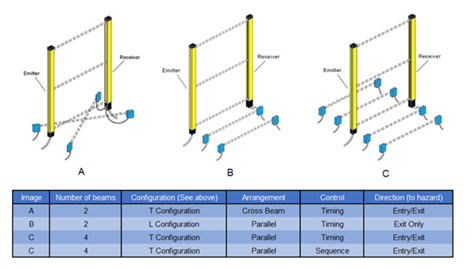

The most common configurations of photoelectric muting sensors are T and L layouts (as shown in the diagram and table below), with 2 or 4 beams either in parallel or arranged as cross beams, and control by way of timing or sequence.

Photoelectric muting can take a variety of different forms depending on the application, the level of safety required and the size of the opening being protected.

Martin Kidman, SICK Manager – Safety (S&W Europe), says: “Highly flexible and configurable, the SICK DMM4 is out of the box certified and Plug and Play, with easy installation and connectivity with the SICK deTec safety light curtain. It’s part of a complete range of SICK safety light curtain products, including light curtains, sensors, fittings and muting modules. Speak to SICK’s application engineers to find out more about what our safety light curtains and the DMM4 muting module can bring to your business.”

Watch Martin’s DMM4 introductory video on LinkedIn here