“Be ambitious. Dream big!” proclaims a giant, brightly-coloured graphic that towers encouragingly above the bustling machine shop crammed with CNC machines at ALM Engineering near Newton Aycliffe in County Durham.

It was this spirit of enterprise and vision that turned necessity into a pioneering robotics innovation. ALM has uprooted machine tending robots, set them on wheels and turned them into freely-accessible and adaptable mobile units that can be quickly and easily repositioned wherever they are needed.

SICK Safety Collaboration

The idea was sparked by the need for a device for the growing needs of the family-run business, founded by Tony Thompson 30 years ago, and also supported by his two sons, Matthew and Daniel. Their development of collaborative robot applications, based on a Universal Robots robot, was so successful for them they decided to perfect and market it to external customers, calling it the CoboTend. Now, a partnership with SICK UK has enabled effortless safety without sacrificing productivity for the CoboTend, a step that has been vital to the product’s continued development.

Through its Cobots Online machine tending automation portal, sales of the CoboTend have become a major contributor to ALM’s business and are expected to double to potentially 80 units in the next 12 months. The Cobots Online portal also offers UR-based robot solutions for sanding and welding.

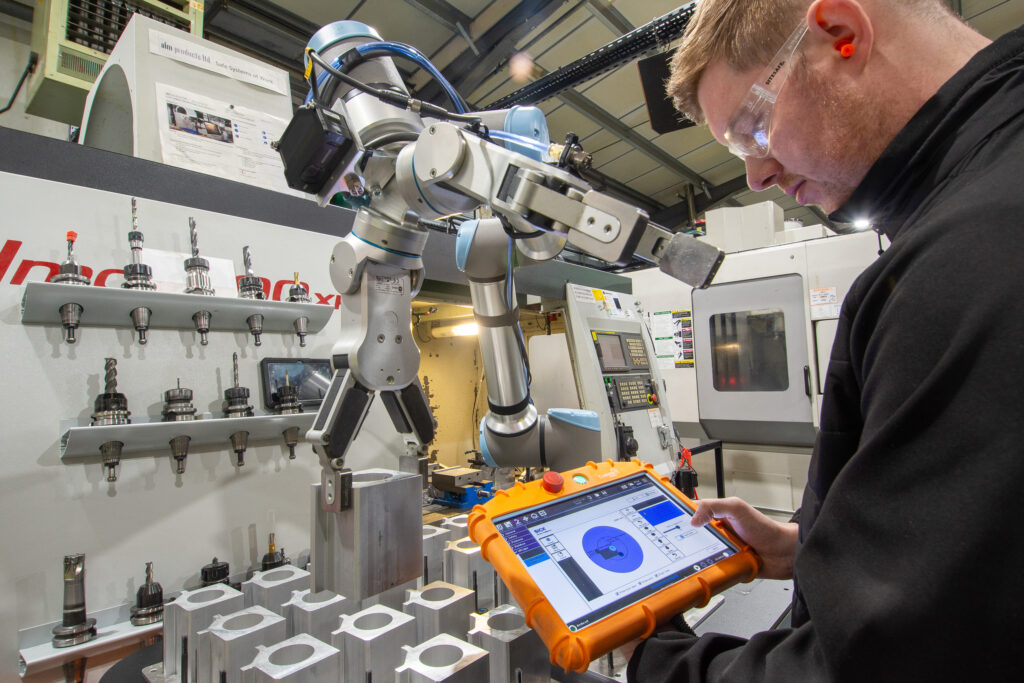

The CoboTend integrates a UR robot into a self-contained and lightweight trolley unit that can be wheeled and secured at a machine in a matter of minutes. A hydraulic mechanism lifts and lowers the wheels and firmly locks the trolley in its new position using floor cups. End-effectors and grippers can be then replaced at the touch of a single button depending on the required machine operation.

Safety with Productivity

Two SICK nanoScan3 Pro safety laser scanners are positioned at opposite corners of the CoboTend’s trolley cabinet. Together, the two laser scanners provide 360° coverage around the robot, enabling it to slow to a safe speed when a person enters the outer of two fields and to stop only when the inner field is breached. This means that the Cobot can continue to operate safety and dynamically based on the proximity of the person rather than simply stopping if anyone gets too close, ensuring maximum uptime and productivity.

Optimising safety with maximum productivity has been an essential element in the continuous development of the CoboTend. A partnership with SICK has enabled Cobots Online to offer machine safety set-up in just a matter of minutes.

ALM’s Commercial Manager Matthew Thompson explains:

“Machine shops like ours are busy places crammed with plant and machinery, and there is not much space in between them. Conventional robots, guarded in cages, would just take up too much room. So, to automate our machine tending we needed a safety system that would enable a robot to operate at speed for most of the time avoiding frequent stops and manual restarts, meanwhile protecting the safety of personnel passing nearby.

SICK nanoScan3 Pro with SBot Speed URCap

The SICK nanoScan3 Pro safety laser scanner is very easy to integrate thanks to the SBot Speed URCap, an easy-to-use safety system that combines SICK and Universal Robots safety technology.

The sBot Speed – URCap is an intelligent safety system which is designed for ease of set-up and intuitive operation. The sBot Speed – URCap was developed by SICK in collaboration with Universal Robots to provide a means to safeguard a robot application whilst achieving high productivity.

It is easy and fast to set up using smart field definition and field teach-in. Simultaneous scan data and automatic field fusion provide feedback though the GUI displayed on the robot pendant to enable set-up, diagnostics, commissioning and validation.

The circular fields, measured from the centre of the robot base, are generated automatically by the system following the teach-in process, which identifies the robot’s surroundings in seconds, including any stationary objects in the monitored area. The safety system is integrated via SICK’s Flexi Soft controller, which fits neatly within the unit’s cabinet.

Designed by Users, for Users

“Until we began working with SICK, with earlier versions of the CoboTend we had to set up the safety systems using a laptop and more complex software,” Matthew Thompson continues. “It took a lot longer, and the software was much less easy to use than it is now. Now, we can combine effortless set-up with peace of mind for our customers.

“The SICK safety is part of the CoboTend’s ultimate appeal: It has been designed by people who use it and understand it. We have developed it for our own efficiency, to get a direct benefit from it. There are other systems out there, but they are developed by robot manufacturers, and not actual users like us.”

The ultra-compact SICK nanoScan3 Pro measures 101 x 101 x 80 mm and is just eight centimetres tall. Despite its size, the nanoScan3 Pro packs in all of SICK’s latest safety laser scanning technology advances, including SICK’s innovative safeHDDM® (High Definition Distance Measurement) scanning and evaluation technology. It enables the highest level of responsiveness when safely adjusting a machine’s speed and direction, even under challenging industrial conditions such as where there are bright lights, sparks, dust and dirt.

The SICK nanoScan3 Pro is a Type 3 device (IEC 61496-3) and can be used in combination with the sBot systems in safety functions up to SIL2 (IEC 62061)/ PLd (ISO 13849).

Return on Investment

Just like many of the high-mix, low-volume manufacturers that use the Cobots Online serves, ALM Engineering is seeing the need for further automation using freely-accessible robots as essential.

Recruitment is getting increasingly difficult and costly, especially since the Covid pandemic, says Thompson. Using cobots also frees up personnel for less mundane and repetitive tasks and reduces the requirement for overtime during busy periods. Cobots Online customers hail from a diverse range of industries from kitchen manufacturers to automotive and aerospace.

“At ALM, we move our CoboTends around all the time,” Thompson continues. “They can do one job in the morning, and another in the afternoon. We can turn the lights off on a Friday and leave them running all weekend.

“Given the price of labour, a CoboTend has a maximum pay-back period of two years. Once our customers have one machine, it’s often not long before they return to buy another one.”