Cost-effective from lot size one, readily available, highly variable

Modular system ensures great scope for customisation.

As versatile as the IDS industrial camera families are, sometimes customer requirements are so particular that a customised development would be desirable. However, this often only makes sense for larger quantities. For this reason, the company has developed the uEye ACP series: its modular design principle allows for a vast range of camera variants. The online configurator helps to put together unusual models that are available from stock. True to the philosophy: be uncompromisingly happy instead of making compromises.

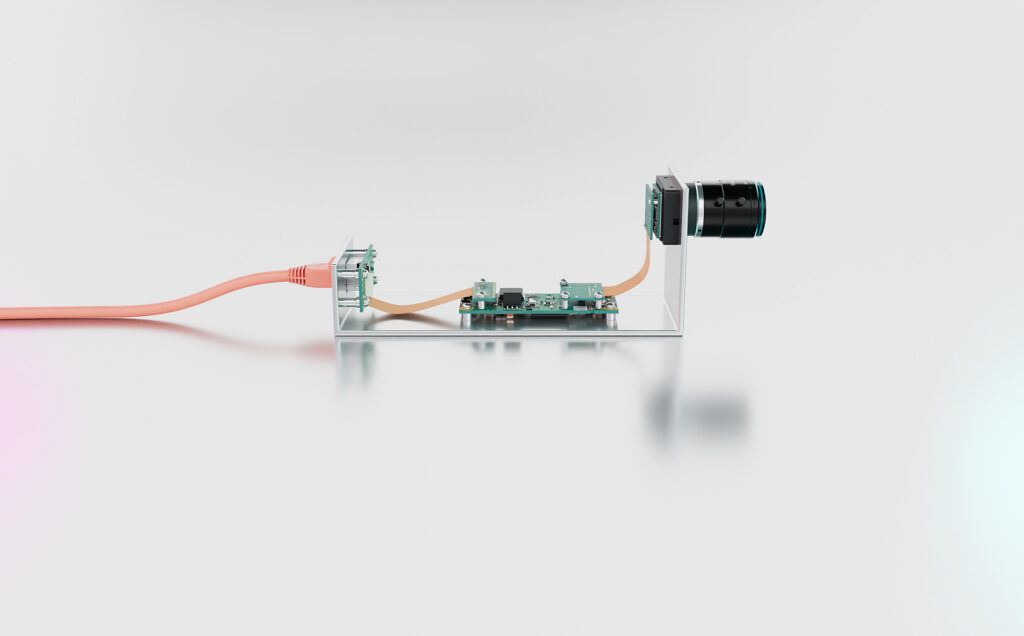

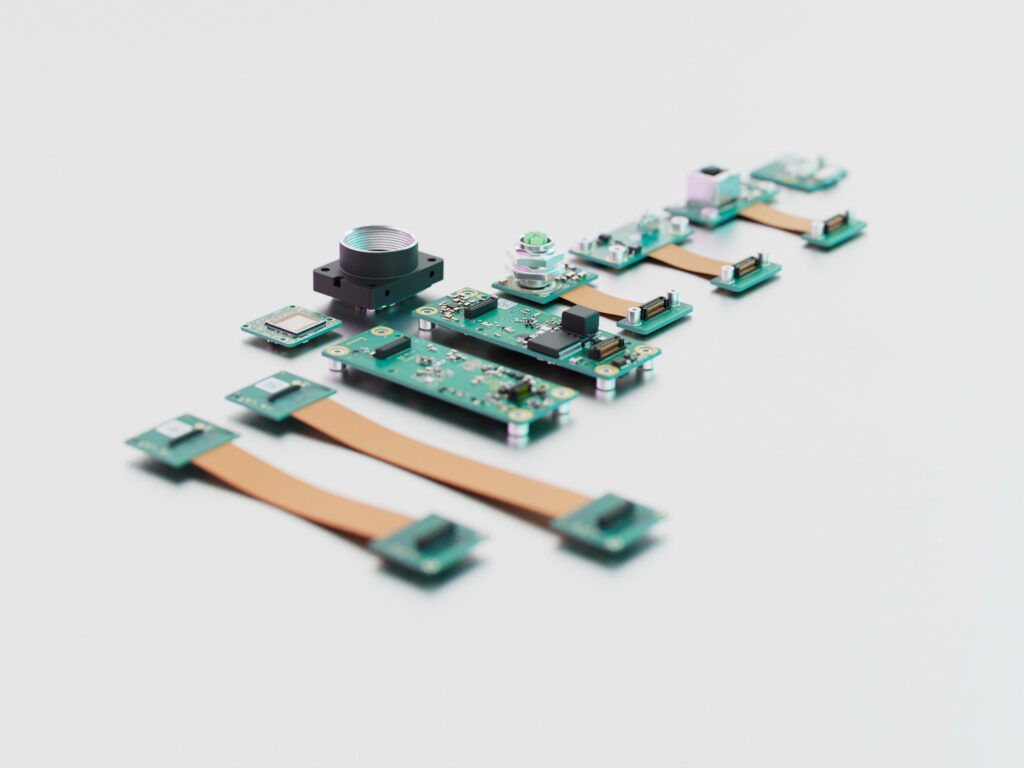

IDS Imaging Development Systems has developed all essential camera components for the uEye ACP series – such as sensor boards, connectors and lens holders – as standard modules that can be freely combined. The range includes USB3 and GigE Vision interfaces, connector boards with various connector options, flex cables and a wide range of image sensors from 0.5 to 20 MP.

uEye ACP allows for a wide range of combinations.

Customised board-level cameras are available off the shelf in quantities as low as one, without the usual development cycles of individual projects. Furthermore, customers have the option of receiving the camera fully assembled or as individual components. As is customary for IDS, careful testing before shipment and quality “Made in Germany” are a matter of course in both cases.

In addition to the uEye ACP product line, the industrial camera manufacturer also takes on customised development projects. On request, an experienced team carries out everything that is technically possible, from individual design to adaptations of the housing, board electronics and connector configuration, as well as software adaptations.

More information: https://en.ids-imaging.com/acp-cameras.html