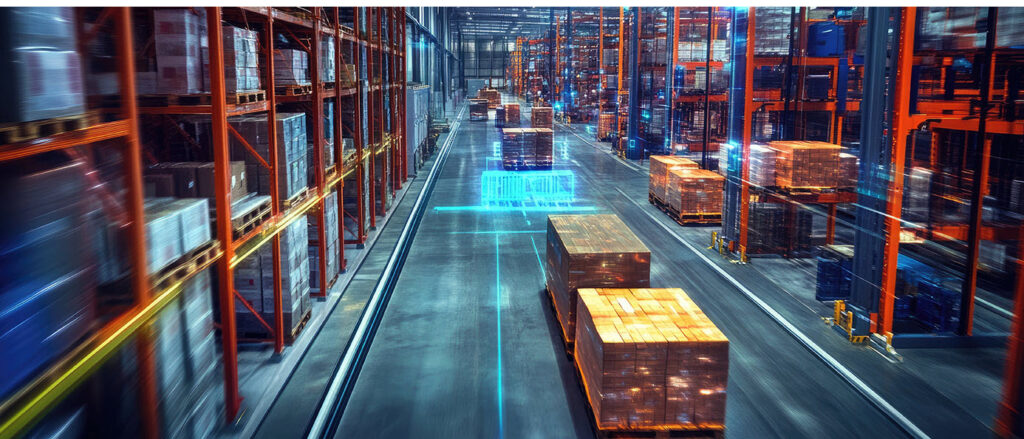

Efficiency, transparency and networking are the success factors of modern intralogistics – and LAPP supplies the essential infrastructure for this. This includes solutions for the smooth running of warehouse operations, through connectable cable sets or a comprehensive product portfolio for all common protocol standards, as well as servo assemblies and drag chain solutions for the optimal flow of goods from the raw materials warehouse through production to the finished product. All requirements for increasing flexibility, innovation or speed, automation and robotics have one thing in common: they require a secure and reliable data and energy supply that can be adapted modularly and intelligently to all requirements.

LAPP as a key player for the intralogistics of the future

With high-quality cabling solutions, LAPP ensures the reliable connection of automated storage and transport systems, enabling time and cost savings. Robust, flexible and durable cables from LAPP can cope with even the most demanding industrial conditions and guarantee continuous data communication – the lifeblood of smart logistics processes.

LAPP also offers predictive maintenance solutions, a pioneering technology that uses sensors and data analysis to identify maintenance requirements at an early stage to minimise downtimes. This makes LAPP a reliable partner for all those who want to take their intralogistics to the next level. For example, LAPP’s eKanban system, which supports customers with digital and intelligent cable inventory management in real time, will also be on the stand. This smart predictive maintenance solution informs users in real time when components should be replaced – for greater operational reliability and fewer unplanned downtimes.