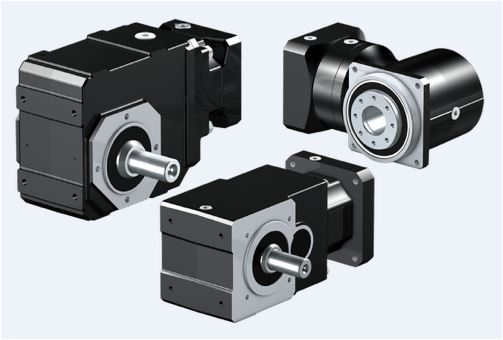

STOBER has further developed its KS right-angle servo gearbox. Delivering ‘power without compromise’, it is now offered not only in two- and three-stage versions, but also in a one-stage version. The new series features robust bearing technology and high-quality gearing.

Compared to other variants, the new one-stage version enables a higher output speed. The gear ratio range has been extended on both the low and high ends for all variants, so customers benefit from receive precise, low-backlash and maintenance-free solutions for highly dynamic requirements.

“Compared to multi-stage variants, one-stage right-angle servo gearboxes are not only more compact, but they are also more robust thanks to the reduced number of components. And since there is only one gear ratio stage, this has a positive effect on energy efficiency,” explains Martin Preece, Head of UK Subsidiary for STOBER.

With their robust bearings and high-quality gearing, KS gearboxes are extremely durable making them suitable for continuous operation, even at high speeds. This series also features very high torsional stiffness. The new one-stage version is available in ratios 2 and 4.

Continues Martin: “By combining the KS right-angle servo gearbox with compact STOBER planetary gearboxes, it can be further expanded into multi-stage gearboxes with ratios from 6 to 400. This more than doubles the previous gear ratio range we have been able to offer so it covers an even wider range of applications.

“The new solution is also robust, rigid and low backlash making it suitable for dynamic requirements. We have also standardized the type of designation and adapted the design of the right-angle servo gearbox to the new, round shape of our planetary gearboxes.”

Flexible and compact

“Just as with the two- and three-stage versions, designers can choose between three shaft designs,” adds Martin. Thanks to these customized output geometries, KS gearboxes can be used for a variety of applications. The two- and three-stage gearboxes can be combined with various STOBER motors via direct attachment. The space-saving drive ensures operators benefit from less weight in addition to high torque and the resulting increased power density. Because the mass moment of inertia of the gearbox is lower due to the absence of the motor adapter, users can take advantage of the full dynamics of the drive.

The brains behind it

Director of Research & Development Mechatronics at STOBER, Artur Wagner, is responsible for the new generation. Having studied mechanical engineering, he began his career with STOBER in Pforzheim, Germany as a computational engineer more than 30 years ago. Today, he is responsible for design and development in the mechatronics department.

Outlines Artur: “We are supporting the consistent optimization of our very broad product portfolio – which also includes the KS right-angle servo gearbox. Thanks to low-friction bearings in the input, higher speeds can be realized, whilst most competitors rely on preloaded tapered roller bearings, which are less efficient.

“We have increased the nominal torques by up to 20 percent and increased the permissible input speed. Together with the smaller gear ratios, the customer can realize significantly higher output speeds – a clear advantage in the market.”

Concludes Artur: “Another highlight is the modular design throughout. By adding planetary gearboxes, multi-stage variants can be implemented flexibly – according to the customer’s exact requirements. Successful lateral thinking in action!”