maxon will present its range of DC motor drive systems for aerospace, space, and drone industries at this year’s Farnborough International Airshow, 22-26 July, in Hall 4, Stand 4028. maxon UK & Ireland’s dedicated engineering team will guide design engineers in drive system specification for applications in fixed-wing aircraft, helicopters, unmanned aerial vehicles (UAVs), drones, space rovers, and satellites.

For aerospace applications, maxon will show precision drive systems including DC and brushless DC (BLDC) motors, gears, and encoders. Developed to comply with the requirements of the AS/EN 9100 Quality Assurance System, maxon’s engineers will explain how its drive systems meet DO 160-G environmental test criteria, as well as testing for standards such as DO-178/254.

The maxon UK & Ireland engineering team will discuss customised drive system development for applications such as control of the Boeing 787 Dreamliner’s air-conditioning system, through to driving the actuators used within Airbus and Bombardier airliners.

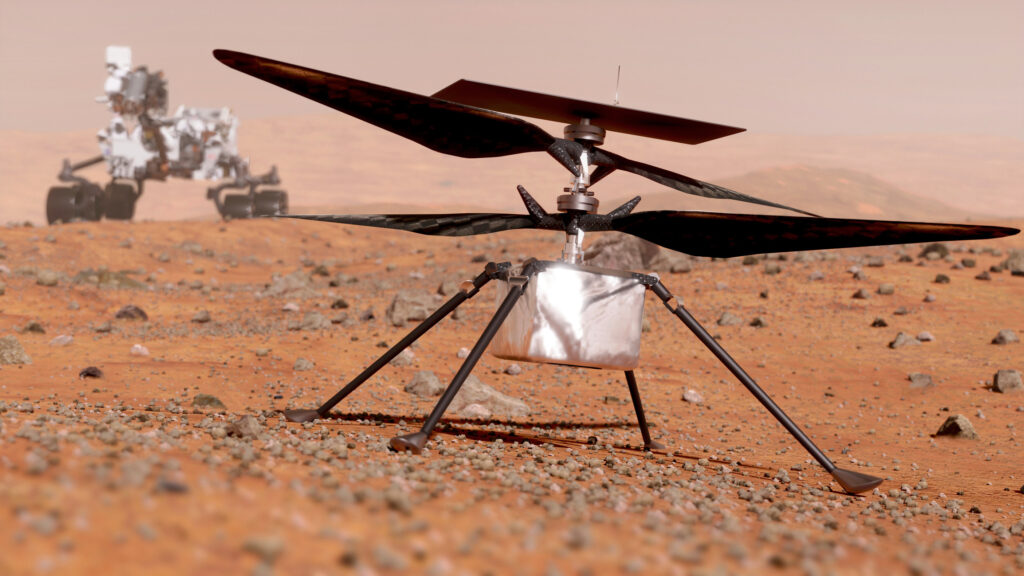

maxon designs its precision drive systems to meet the highest levels of reliability in the most demanding environments, an approach demonstrated in the collaboration between NASA and maxon in the Mars Rover projects. At Farnborough, maxon’s engineers will explain how its drive systems have been used on every NASA Mars Rover, the first launched over 20 years ago, including the recent ground-breaking Ingenuity Mars drone that endured over 70 flights on the red planet.

Back on Earth, as drone developers look to expand into wider commercial and industrial applications, from parcel deliveries through to infrastructure inspection, the demands on drone propulsion are increasing. At the show, the maxon UK & Ireland engineering team will discuss how its propeller, motor, and controller system has been tested to meet DO 160-G criteria to ensure safety, while the latest developments are also optimising power efficiency.

“The aerospace and space sectors have always relied on high reliability, precision drive systems, but new demands facing these applications are pushing DC motor system development further still,” explains maxon UK & Ireland’s head of aerospace and space applications, Andrew Gibson.

“Space exploration is set to endeavour deeper into the universe, demanding even more reliability, while terrestrial projects are requiring ever greater efficiency and control. This means that every project has specific requirements from its electric drive system. We’re at the Farnborough International Airshow to support aerospace and space engineers in the integration of the optimum drive systems for their requirements,” says Andrew.

Find out more about maxon’s drive systems for aerospace and space technology.