SICK’s comprehensive range of machine vision hardware, including the new Inspector83x AI camera, combines with the powerful NOVA software platform and a team of in-house experts to offer a service that can solve the most challenging machine vision tasks.

At the UKIVA show, SICK has expanded its comprehensive machine vision portfolio with the UK launch of the Inspector83x 2D AI smart camera, which harnesses the power of SICK’s user-friendly NOVA common development platform.

The next-generation 2D vision camera is the fastest on SICK’s NOVA platform, extending the company’s comprehensive portfolio of 2D and 3D machine vision products. SICK’s experts work closely with customers to create tailored solutions to each automated inspection and measurement challenge, optimizing the potential of its machine vision software and hardware.

SICK’s NOVA platform empowers users to build their ideal machine vision applications

The scalable NOVA common development software platform builds on SICK’s rich machine vision history to place the power of machine vision and robotic guidance in users’ hands, providing an easy way to quickly add, combine, and customize machine vision tools. It features a user-friendly web interface and AI capabilities, reducing complexity and enabling anyone to build the most challenging machine vision applications without requiring expert machine vision knowledge.

NOVA is continually evolving and recent updates have included new tools and features such as suppress edge artifacts in AI anomaly detection, hardware acceleration to decrease analysis time for the AI classification tool, 3D box detection, and added list functions in the Expression tool. The software platform’s AI functionality makes machine vision tasks more achievable than ever before by teaching with examples instead of manually setting up rules.

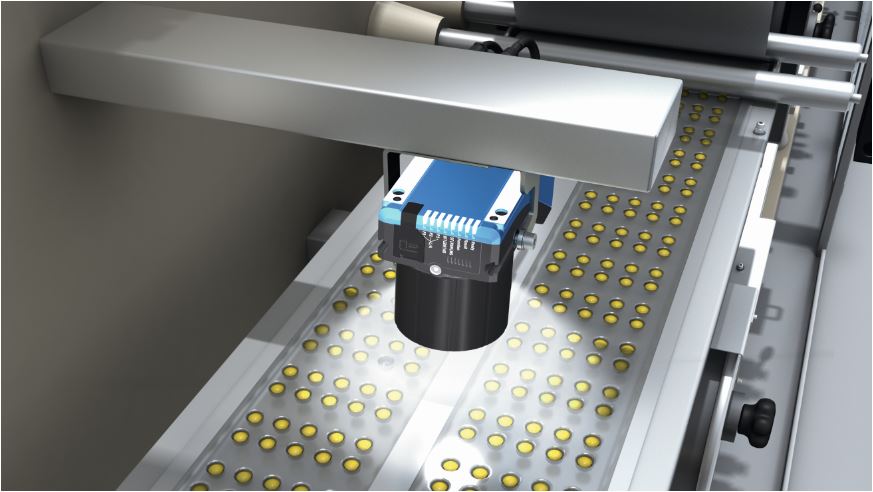

Potential applications for SICK’s NOVA-powered machine vision technology and deep learning are limitless, with existing applications ranging from identifying the presence of transparent objects in manufacturing and ensuring items are placed accurately in food packaging, to speeding up assembly processes and ensuring consistent quality in fish processing. SICK machine vision products empowered by NOVA are used across diverse industries, including logistics, automotive, FMCG, robotics, and process, and by end users, OEMs and integrators. With SICK, NOVA applications can start with just a single camera, while advanced users can expand custom developments further using Lua programming and HALCON.

An enhanced generation of inspection capabilities with NOVA powered Inspector83x

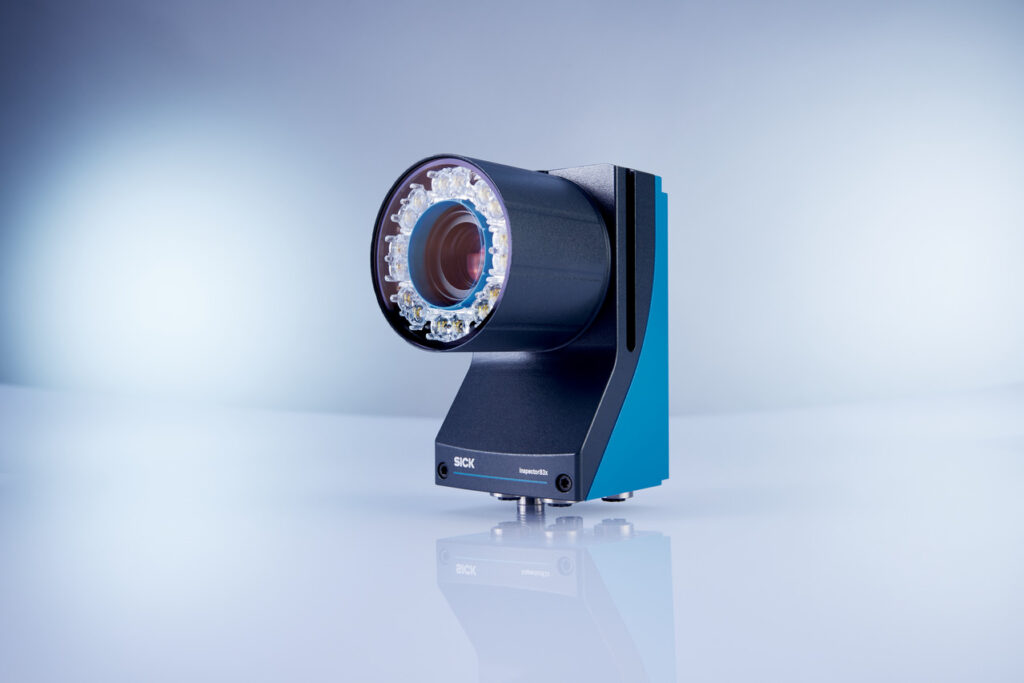

An out-of-the-box solution, the Inspector83x’s integrated AI functionality makes the most challenging machine vision tasks possible with high accuracy and high-speed data transfer over industrial networks. With up to 5 MP resolution, a powerful quad-core CPU and built-in illumination, the SICK Inspector83x is an impressive all-in-one performer, processing AI inspections directly on the device at high speed with no need for external machine control.

Using NOVA and the Inspector83x, any product design or batch changes can be quickly added in the same way by an operator from the production line. The no-stress teach-in capability of the SICK Inspector83x can be used by non-specialists to configure powerful, high-precision AI inspections at full production speeds for common inline inspection tasks, including complex inspections of medium to large scenes, evaluating products with unpredictable features, and verifying complex assemblies. By showing the camera as little as 5 examples, initial inspection results can be up and running in minutes.

For complex scenarios, users can access the computational power of the SICK dStudio cloud service to train their own neural network and export a small file to run on the Inspector83x. The easy-to-use dStudio service also offers the unique advantage of colleague collaboration and data management.

SICK product manager Viktor Smedby, the architect of the Inspector83x, says, “The Inspector83x is the ultimate quality control tool. For applications like quality assurance, detection and sorting tasks, the Inspector83x has yet to meet an application it can’t solve. We have designed it to make quality control user-friendly and efficient, offering the perfect solution for demanding inspection tasks, even at high process speeds. In 2024, new capabilities will be added to the Inspector83x, including colour imaging.”

Nathaniel Hofmann, SICK UK Market Product Manager – Machine Vision and Measurement, adds, “At SICK our real value lies in our ability to offer full-spectrum machine vision solutions. We’ve got a comprehensive hardware and software range. Tell us what you need and we will use our machine vision expertise to make it a reality.

“The potential of NOVA-empowered machine vision is vast and we relish a challenge, working alongside customers to create bespoke solutions. As one of the very first manufacturers of 3D machine vision cameras, we bring SICK’s vast vision sensor experience, knowledge and quality to your operations.”