Electrical design engineers are facing mounting challenges in terms of complexity, time pressure, and cost. When combined, these factors make it essential that professionals have access to smooth, simple workflows.

However, this is often far from the norm. Traditional design workflows can suffer from inefficiencies and engineers frequently have to navigate complex menu structures in their software, engage in repetitive tasks, and deal with excessive communications for coordination. These cumbersome steps not only waste time but also interrupt the flow of work, leading to reduced productivity and leaving room for errors to creep in.

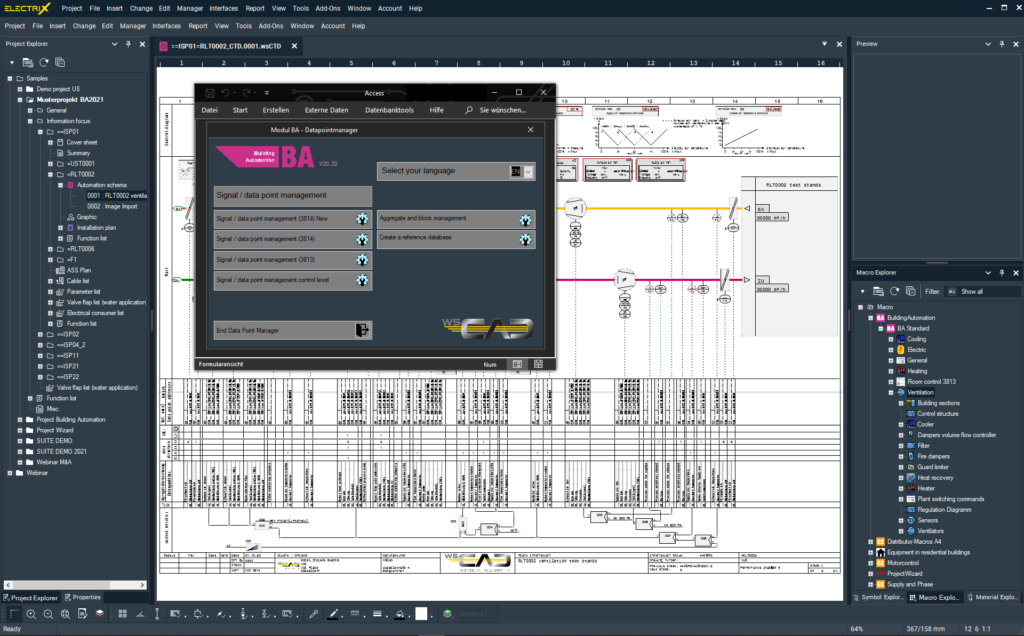

Fortunately, this is somewhere that modern electrical CAD (E-CAD) software can deliver real, tangible benefits. By streamlining and simplifying the electrical design process, this technology can address the core issues facing design engineers by offering tools that enhance efficiency, reduce time-consuming manual steps, and guarantee precision.

Fewer clicks, same result

One example of these traditional inefficiencies is the method of placing components in circuit diagrams. Though it’s not especially complicated, this process typically involves navigating through multiple menus, opening several windows, searching for components in databases, and manually placing them on the diagram. This can take up to 20 steps, interrupting the designer’s concentration and slowing down the overall process.

For those looking to enhance their workflows and achieve faster project completion, exploring solutions like WSCAD’s ELECTRIX software could be a game-changer.

A more efficient approach is to ensure the designer is using E-CAD that offers a streamlined ‘search & click’ function that allows them to quickly find and place components using a simple search field. This function, included in WSCAD’s ELECTRIX software, can cut the process of placing components from 20 steps to just two clicks of the mouse.

By minimizing these interruptions, designers can stay focused, complete projects faster, and reduce errors, ultimately leading to a more efficient and productive workflow.

Boosting efficiency, reducing errors

Another way in which modern E-CAD software can deliver time savings is by simplifying the complex process of designing electrical systems and components such as control panels. These tools can help at every stage, all the way from placing the first components through to fabrication of the designed control cabinets.

For example, the software can help with the precise task of component placement. With it, designers can quickly find and place enclosures, doors, and mounting plates, align DIN rails and cable ducts and rely on the software to automatically route connections and calculate wire lengths. Again saving time and reducing mistakes.

On top of this, E-CAD can also provide vital error-checking services. The software shows the fill level of cable ducts, suggesting larger ducts or better placements to avoid overfilling, while the 3D view checks minimum distances and potential conflicts for space, ensuring everything fits perfectly and safely before production of the cabinets begins.

Once the design is finished, the generated data can be used directly for various manufacturing tasks. Firstly, the data is utilized for printing labels for cores and wires, general stickers, and QR codes. Secondly, the wire data sets are transferred to wire manufacturing machines for producing wires and wire sets in the control cabinet. Lastly, the data is used for manufacturing mounting plates, cabinet doors, and cabinet housings through automated drilling, milling, laser cutting, and thread cutting on NC machines from well-known manufacturers. This integration skips the need for extra mechanical CAD software, speeding up the production process and reducing the time pressure on designers.

Implementing shorter, automated processes

An excellent real-world example of how processes can be overhauled and automated can be seen in the work of Bruckmann Steuerungstechnik GmbH (BSG). Located in North Rhine-Westphalia, Germany, BSG has been crafting automation solutions for the plastics industry since 1995.

BSG has long focused on reuse and automation in electrical design. Once an order is placed in their ERP system, all of the items associated with it can be transferred to WSCAD’s software using a custom configurator tool. The software automatically assembles complete circuit diagrams and control panel designs. It also generates documentation, including manufacturing data, and sends the bill of materials back to the ERP system to start the ordering process.

According to BSG, this automated setup drastically reduces planning time. For standard projects, the company reports an 80-90% reduction, while non-standard projects still see a 20-30% time saving. Additionally, generating electrical documentation ensures consistent quality, structure, and layout, making service and maintenance much easier for BSG’s customers.

Tackling complexity

Modern E-CAD software offers significant advantages in tackling the complexity, time pressures, and costs of electrical design. By streamlining workflows, reducing repetitive steps, and automating processes, engineers can work more efficiently and effectively.

For those looking to enhance their workflows and achieve faster project completion, exploring solutions like WSCAD’s ELECTRIX software could be a game-changer. Embracing these advancements is a key part of staying ahead in the increasingly demanding field of electrical design.