With the technology continuing to advance year on year, lasers are not only finding their way into new applications, but are also now available in many different configurations, including a range of handheld systems for cleaning and welding. The ability to move and manipulate the laser by hand makes it possible to use the technology in applications which would otherwise be difficult or impossible with the more conventional laser configurations.

As for any laser application, safety is paramount and those using hand-held laser welding technology must also follow industry safety procedures and guidelines relating to their attire and eye protection. As hand-held laser systems operate without physical protective enclosures there are some additional challenges surrounding risks relating to fumes and diffused light from the laser.

Bromsgrove based TLM Laser, the UK and Ireland distributor for laser protective equipment specialist Univet, are pleased to announce the launch of Univet’s revolutionary “MASTR” laser welding helmet. This innovative helmet is specifically designed to protect against the scattered and diffused light generated during welding processes performed with hand-held laser systems which emit in the near infrared. The complete solution combines the helmet shell, manufactured from a special compound material which is resistant to laser radiation, with a laser protective filter and an auto darkening welding filter. The helmet shields the eyes and the face of the user from diffused laser light and from optical radiation generated during the welding process.

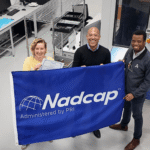

TLM Laser have launched Univet’s revolutionary “MASTR” laser welding helmet in the UK and Ireland

Weighing just 700g, the helmet offers maximum comfort during long-term use and incorporates a system to adjust the helmet height and inclination. The laser protective filter has a wide absorption range and guarantees the visibility of major laser aiming beams (630-670nm) whilst the auto-darkening welding filter (ADF) has digital controls and a shade ‘3’ light state.

As a business, TLM Laser has over the years built up a comprehensive portfolio of laser processing technologies which is supported by ancillary equipment ranging from Laser Safety Eyewear, Extraction Systems and right through to complete Laser Safe Enclosures, designed and built around the specific application. Add to this the company’s hard-won expertise in applying lasers for cutting, welding, marking, and cleaning applications and potential users of laser technology can leverage from a truly holistic approach to laser system integration.