Ultima Forma, a UK-based technology pioneer, has joined forces with global leader in collaborative robotics (cobots) Universal Robots, to tackle a critical challenge: net-zero aviation. The partnership combines advanced robotics with cutting-edge materials science to help power the next frontier in alternative-propulsion technology from as early as 2035, with the long-term aim of reducing global CO2 emissions by up to 4%.

Liquid hydrogen fuel is one of the most promising technologies to reduce aviation’s climate impact, but it has to be stored in tanks at temperatures below -250°C. This means that the materials used need to be ductile and strong at these very low temperatures while also being lightweight as every kilogram is critical in an aerospace application.

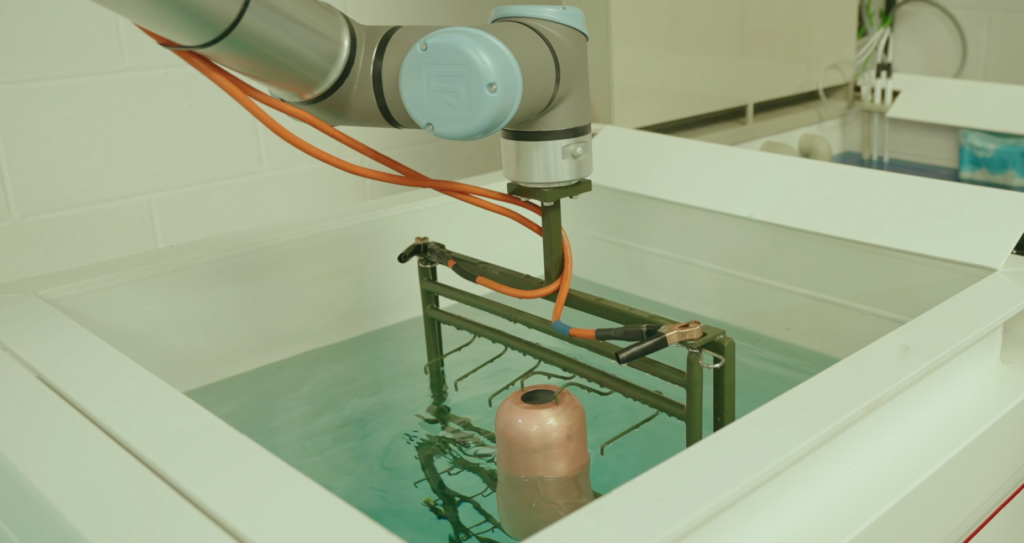

Ultima Forma has developed a multi-layer solution which combines very thin layers of different metals to tune the properties of the material to remain strong at low temperatures. However, the process needs to be done with great precision each time.

Universal Robots’ UR10e provides Ultima Forma with the means to control the deposition of the metal in each step of the process delivering up to 0.1 millimetres precision – something that is not possible with human workers alone.

“The high level of control that advanced robotics allows us to have is essential for the quality standards required in aerospace manufacturing,” says Professor Andy Bushby, Chief Technology Officer at Ultima Forma. ”This precision is only achievable with Universal Robots’ cobots as it guarantees the quality and repeatability of those parts, providing our customers with assurance of nanometre-level consistency. Our vision is to use material science, advanced technologies and key partnerships, with companies like Universal Robots, to accelerate the shift toward sustainable energy and help shape the future of aviation.”

With little to no coding or robotics experience required, Ultima Forma was able to get the UR10e unboxed and up and running to a basic level within four hours.

“Our collaboration with Ultima Forma is the perfect example of how advanced robotics can play a critical role in transforming industries and addressing global challenges,” adds Mark Gray, UK & Ireland Country Manager at Universal Robots. “Our cobots are designed to deliver the kind of precision and flexibility needed to tackle complex manufacturing challenges in industries like aerospace. We are proud to be playing a role in Ultima Forma’s mission to decarbonise the aviation industry and look forward to seeing this go beyond the R&D phase in future.”

You can find out more about the Ultima Forma case study at https://www.universal-robots.com/case-stories/ultima-forma/.