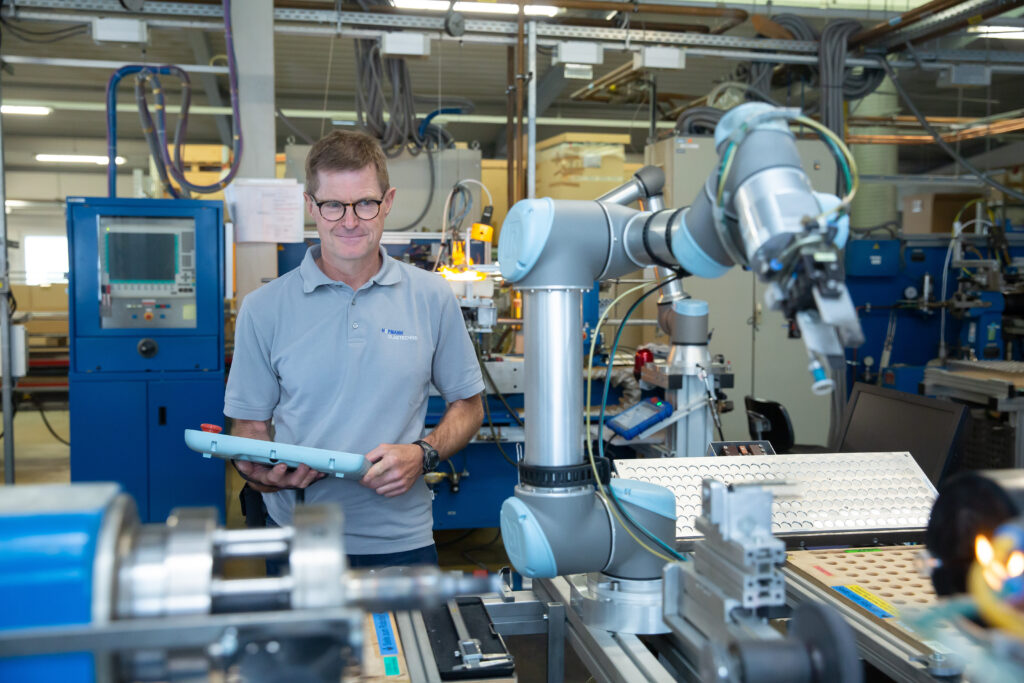

Universal Robots, the world’s leading collaborative robot (cobot) company, continues to transform manufacturing environments with the delivery of impressive productivity gains, as the first case stories of deployment of its newest cobot – the UR20.

With manufacturers facing an unpredictable global economy and increased labour shortages, increasing efficiencies will be a key challenge in the pursuit of profitable production lines for many in 2024. As customers using the UR20 have discovered, accelerating automated manufacturing processes offers the ability to increase consistency, eliminate bottlenecks and reduce downtime due to a lack of personnel or space needed to meet peaks in demand.

One success story from the programme is that of Ornua Ingredients, part of Irish Dairy co-operative Ornua, which specialises in the marketing and sales of dairy products. One of the business’ most labour-intensive operations was end-of-line palletising in which workers manually handle a variety of heavy-weight dairy products.

Founded on a culture of innovation and collaboration, the business has been using the UR20 to increase operational efficiency, develop talent, and deploy human resources to best effect across the company’s Herefordshire site.

“We looked at palletisation as the first area to deploy automation due to the number of human resources we required,” comments Jack Cotton, Continuous Improvement Lead, Ornua. “When we learned about what the UR20 could do, we were excited by the capabilities, both in terms of the capacity it could lift and the arm reach, which were perfect for the delicate products we required support for. The benefits of its deployment have been nothing short of brilliant, with increases in consistency and productivity boosts very clear to see.”

“It’s been great to see the UR20 used as part of so many transformative manufacturing journeys this year amongst such a diverse range of customers,” comments Stacey Moser, Chief Commercial Officer, Universal Robots. “We are working with many progressive customers on their 2024 budget and plans as they are tailor more of their budgets towards automations and cobot technologies that are now proven and safe Automation is no longer an afterthought for customers focused on productivity, quality and gaining efficiencies. Businesses that fail to invest today risk sacrificing years of hard-earned momentum to more forward-thinking competitors.”

To learn more about how the UR20 and other cobots can support your business, visit www.universal-robots.com