Waveforce Energy is about to begin tests, the first of their kind, that could enable wave energy farms to be used in any maritime location around the world. Comprising a specially designed turbine and mathematical modelling that optimises yield and efficiency, Waveforce Energy has partnered with maxon to achieve power generation through brushed DC motor technology.

Wave power technology test for power generation breakthrough

There’s a growing need to power an expanding range of electrical devices in offshore marine locations. For purposes such as inspection and maintenance, search & rescue, weather monitoring, and security, devices such as drones and underwater autonomous vehicles (UAVs) are increasingly relied on, alongside various types of sensors and communications equipment.

While these devices typically require relatively modest power, supplying them with electricity in a distant maritime environment, whether to power them directly or to charge their batteries, is a challenge.

Seeking to achieve a flexible way of powering applications like these at sea, Waveforce Energy is a start-up business based in Dublin that is harnessing the ever-present motion of ocean waves. The company hopes that its approach could one day be a flexible mode of power generation at any marine location.

Wave energy conversion technology

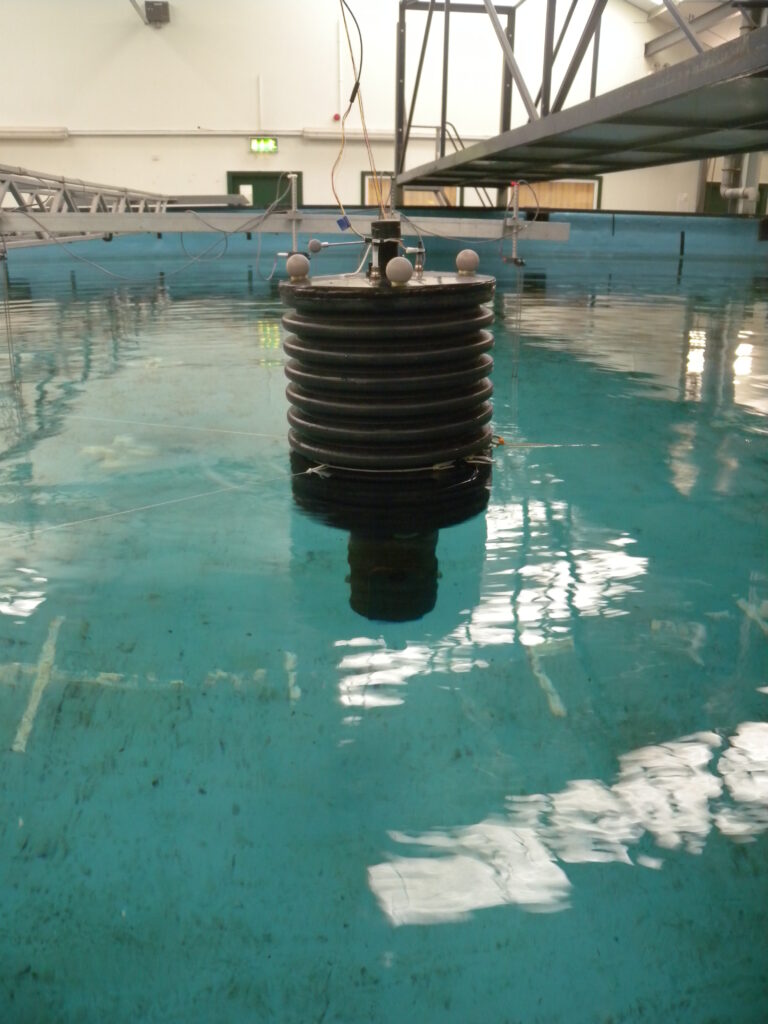

The technology is based on a generator housed within a buoy, forming a device known as an oscillating water column wave energy converter. The motion of a wave compresses the trapped air inside the buoy, forcing it through a turbine that drives a generator. To optimise yield, a chain of buoys can be linked to form a wave energy farm.

While this technology was first theorised in the 1940s, until now, it hasn’t been deployed for regular use in the real world. However, after nearly 10 years in development, and with funding from Enterprise Ireland, trials are shortly to begin at the Lir National Ocean Test Facility in County Cork.

The new technology uses an updated turbine design that has been 3D printed for the initial prototype. The turbine is housed within a buoy, 50cm wide and just over a metre in length. From each test buoy, Waveforce Energy is hoping to generate 20 Watts, achieved from a relatively low-level wave.

20 Watts might sound small, but following the tests, the buoys could potentially be increased in size to a practical limit of 16 metres diameter. With a scale-up in size, this would deliver a significant increase in power.

Wave property mathematical modelling

Theoretically, multiple wave energy converter arrays, consisting of thousands of buoys, could be distributed in oceans throughout the world, and their generated power could be combined in the same way that many individual photovoltaic solar panels pool together. But, unlike solar panels, wave energy converters can generate power night and day, and throughout all seasons.

Along with the innovation in turbine design, developed specifically for wave dynamics, Waveforce Energy’s proprietary expertise lies in the mathematical modelling that optimises power generation. To achieve this, the model takes into account multiple wave attributes, including wave height and wave frequency.

The main benefit of this approach is that a single model includes the complete process, from the incoming wave to the outgoing electric power. As all stages of wave energy conversion are included, the model can determine how much power can be generated based on the properties of the waves.

However, wave properties differ for every location, so to optimise power generation from each installation site, the wave energy conversion array requires a specific set up. The mathematical model enables system tuning according to all key wave properties, enabling the devices to be installed in any ocean-going location, and operate with high efficiency.

Motor technology for power generation

Part of the flexibility of the wave energy conversion array is that it can also generate power on a turning tide. The air pressure-driven turbine is connected to a DC motor, forcing it to spin. In turn, the motor operates as a generator, with the motion of its rotor inducing a voltage that generates electrical current.

Potentially located in distant seas, these motors would have to survive extremely tough conditions, and with little of chance of a fast repair or replacement, this makes reliability crucial. To optimise power yield, the motors must also be extremely efficient.

Waveforce Energy approached maxon for support via the Young Engineers Program that supports academic and start up projects. maxon engineer, Martin Leahy, provided application support, specifying a brushed, coreless, 65mm DC motor. The brushed design increases simplicity, eliminating the need for additional electronics, ensuring reliability. Meanwhile, the coreless approach that removes the traditional iron rotor, reduces weight and inertia, optimising power generation per wave.

Reliable motor operation is essential

Importantly, low inertia, combined with maxon’s rigorous testing, also means that the motor is highly predictable in its behaviour. For Waveforce Energy, this enables greater accuracy in power generation modelling. As the wave energy conversion buoy could potentially be used in any location, consistency of output data is crucial to accurately estimate the power yield, and to tune the array for the wave properties specific to each marine environment.

The Waveforce Energy team is currently heading for test tank trials, and depending on the success of the upcoming tests, the team will then progress to replicate real world conditions. This will include trialling the buoys in sub-optimal wave conditions, simultaneous multiple sized waves, as well as the maximum scale waves that could be experienced in extreme situations. After that stage, sea trials await.

For more information, visit www.maxongroup.co.uk