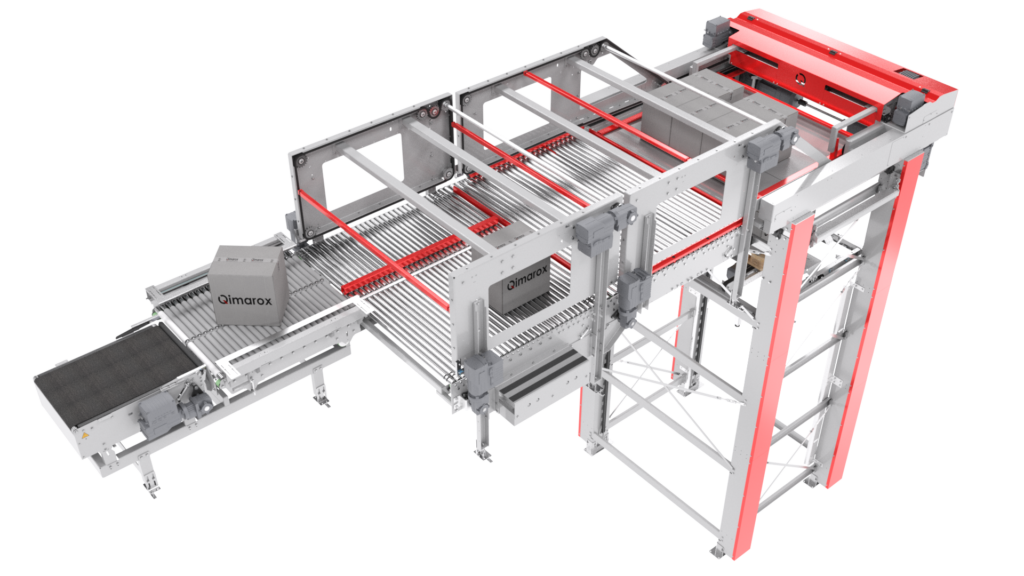

CKF Systems are delighted to introduce the new palletising solution developed

by Qimarox for logistics operations where palletising goods from containers

happens frequently. The Qimarox Highrunner HR9 is the only solution in the

market that comes complete with a unique pattern generator allowing the

system to stack boxes of almost any size on pallets at high speed without

specially trained technicians generating a fresh pallet pattern for each new

product.

CKF Systems is the sole Silver Partner for Qimarox in the UK and has a wealth of experience

integrating Qimarox product lifts and layer palletisers. This case study

https://youtu.be/7IIAZVB3KPU provides information on CKF’s recent layer palletising

installation for Laithwaites wine.

The manual unloading of ‘loose loaded’ containers is physically demanding, time-consuming

and unattractive work. The removal process from the containers one by one and then

manually stacked onto pallets, can lead to damaged packaging and goods if stacked

carelessly or dropped.

Investment in the automation of the palletising process will provide companies the solution

necessary to meet the increasing demands of the global supply chain to empty containers

more efficiently and improve the working environment for personnel.

See the video of the HR9 in action here:

https://youtu.be/uJdhAcZQdaU?si=sftGABp_sRGlOUta

Smart pattern generator with 3D scanner

CKF Systems design and build the conveyor systems supporting the Highrunner HR9

palletiser and integrate a 3D case product scanner which automatically captures the

contours and dimensions of the cartons. The data forms the input for the pattern generator

which calculates multiple stacking patterns based on that information, this is then displayed

to an operator highlighting the preferred pattern. The pattern is selected to offer the best

stability, pallet utilisation and speed of case handling. Once selected the pattern can be

saved into memory against that product and recalled, as required automatically, on

recognising the product barcode. This process no longer requires highly trained and

experienced technicians or callouts from specialist programmers each time a new product is

received.

CKF Systems has been operating as a leading turnkey automation provider in the UK since

1988 and has a wealth of experience integrating state of the art automation solutions for

our customers who range from SMEs all the way up to some of the biggest global

corporations.

CKF are pleased to have achieved some of the highest accolades and partnerships with

Qimarox, Intralox, ABB and Interroll for many years, demonstrating their commitment in

supporting CKF’s capabilities.

With the introduction of the Qimarox Highrunner HR9, CKF can expand their container

unloading offering to customers throughout the UK who require a robust and reliable

solution to palletise varied and ranging products.

CKF offer the full turnkey solution from concept to installation with all our conveyors,

software and electrical system designed and built in-house at their offices in Gloucester. The

systems are then installed, commissioned, and supported by CKF full time site teams.

To learn more about the HR9 Containerised product palletiser, CKF’s robotic and product

handling capabilities please visit www.ckf.co.uk or contact us directly on [email protected].

For more information please contact:

Jen Halliday

E-mail: [email protected]