Basingstoke, U. K. July 3, 2024 – Aerotech, the specialist for motion control and positioning systems, will be exhibiting at Micronora 2024 in Besançon (France) from 24 to 27 September on the joint CLP (Club Laser et Procèdès) stand. Trade visitors will be able to gain an insight into the innovative IFOV (Infinite Field of View) function for expanding the field of view during laser scanning. With the AGV5D galvo scanner, the experts will also be presenting a new control approach for flexible and powerful 5-axis laser micromachining. The latest features of the “Automation1” motion control platform will also be on show.

Aerotech has been supplying standard components and solutions such as motors, drives, controls, positioning tables, galvo scanners and much more for more than 50 years. Customised motion subsystems include positioning systems on granite structures with a base frame and vibration isolation as well as external measuring systems.

“Micronora, which takes place every two years, is a very special event in our calendar, as it brings together Europe’s leading expertise in the fields of microtechnology and micro nanotechnology,” emphasises Simon Smith, European Director at Aerotech. “With our focus in laser and measurement technology as well as additive manufacturing support for high-precision positioning systems in the nanometre range, we always attract a lot of interest here.”

IFOV in laser processing

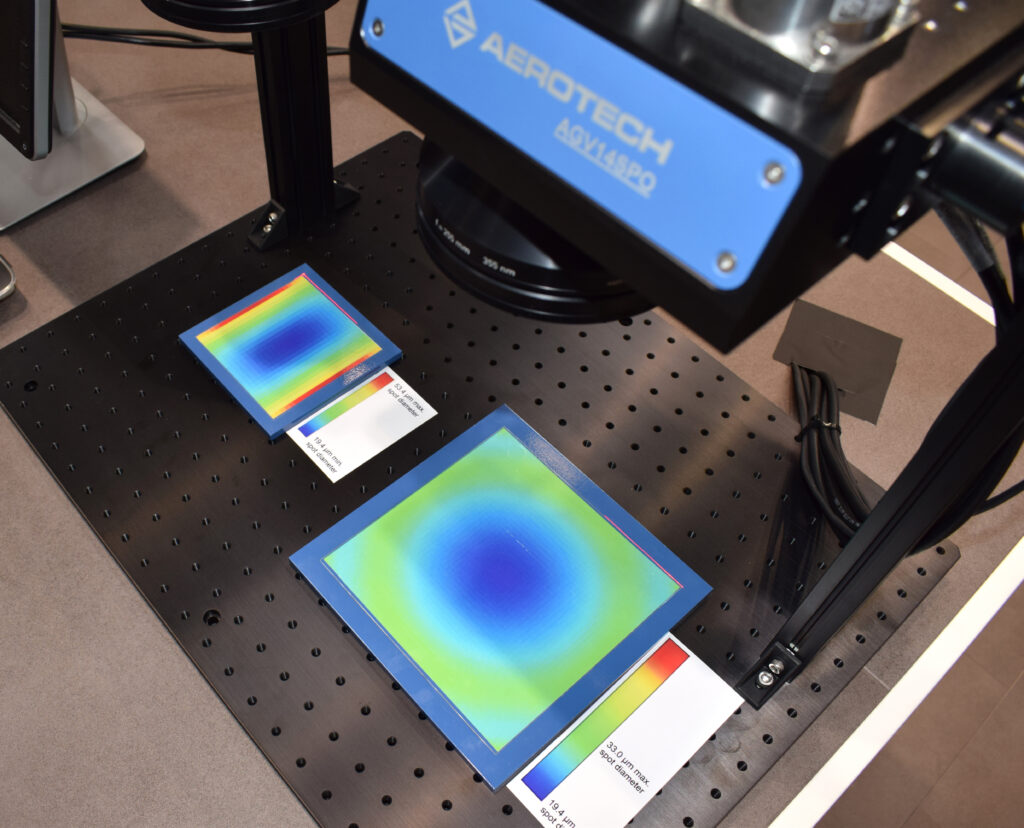

A central theme of Micronora is the production of micro actuators, micro sensors and micro displays. At the joint CLP stand in Hall C, Aerotech will be presenting an innovative solution for synchronising linear or rotary servo axes with laser scanners. The extended field of view significantly improves throughput and eliminates seam errors and part quality problems caused by overlapping and mismatched laser processing. By combining the highly dynamic capabilities of galvo scanners with the travel range of servo tables, parts that are significantly larger than the conventional field of view of a scanner can be processed continuously without having to join individual work areas together. One example of this is the production of OLED displays.

“Multi-scanner systems with IFOV controllers from Aerotech enable complex, large-area and highly dynamic laser processing between multiple axes and an expansion of the field of view without the familiar stitching,” summarises Simon Smith.

Laser micromachining with the AGV5D

With the AGV5D, Aerotech is also bringing a new laser micromachining scanner to the trade fair. The high-precision 5-axis laser scanner creates conical, cylindrical and angular holes or other complex contours and geometries that would be impossible or very time-consuming to produce with 2D or 3D scanners.

The reason for the high precision and flexibility lies in the 5 degrees of freedom (DOF). The laser beam can be scanned and moved simultaneously in 5 axes by the AGV5D: Spot placement in the field of view (2-DOF), depth of field (1-DOF), precession angle (2-DOF). The 5-axis laser scanner is controlled via the Aerotech motion control platform Automation1, which can also handle workpiece positioning and laser control at the same time. The result is high-precision, complex components in the micrometre range.

Intuitive control for all applications and systems

Speaking of Automation1: the user-friendly motion control platform is being continuously developed by the experts at Aerotech and will also be presented in its latest release at the trade fair stand. “We have once again been able to incorporate some important technological features,” emphasises Simon Smith. “These not only make programming easier and more intuitive, but also make the platform more powerful overall.”

For example, the new XA4 PWM drives from Aerotech can now also be integrated. The compact single and multi-axis servo motor drives are designed for installation in control cabinets and are available from Aerotech for a comparatively low price.