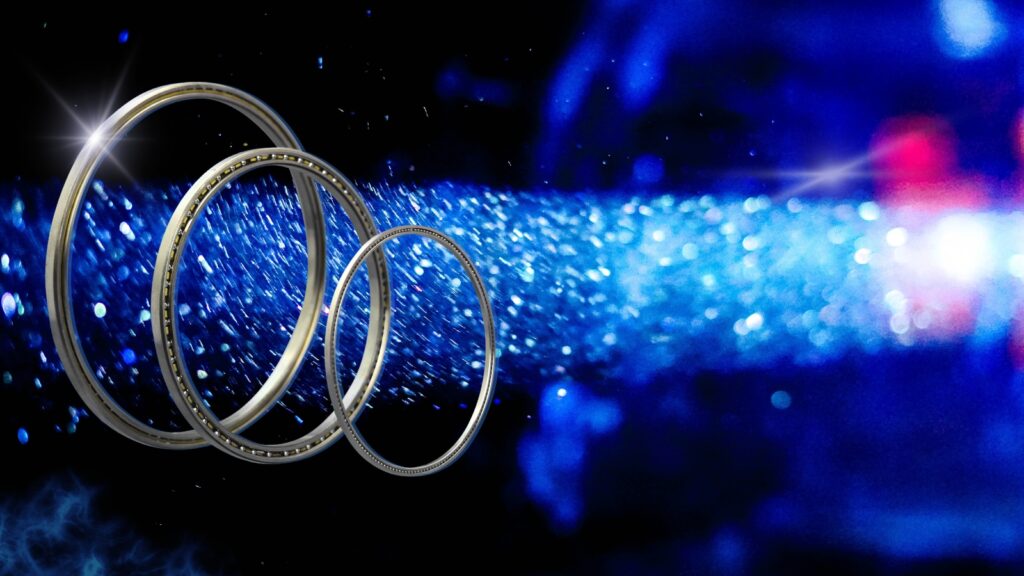

Bearings…maybe a less understood and appreciated component given the complexity of today’s increasingly automated manufacturing systems, yet such a vital part in any kind of machine that requires smooth and reliable motion control. The technology of bearings is well documented, especially when metal-forming processes were significantly improved over 200 years ago, which became the basic ingredient for many of today’s bearings. Fast forward to now and the rapidly increasing demand for precise motion control and advanced automation systems has resulted in the development of an extensive range of different designs’ including various types of the most compact, lightweight and versatile thin section bearings.

Located near Oxford and surrounded by a cluster of high-technology companies involved in industries such as; motorsport, nuclear, medical, defence and aerospace is precision bearing specialist CARTER MANUFACTURING. As the European distributor of Silverthin precision thin section bearings Carter’s expert staff are all highly trained engineers providing customers with a unique blend of experience and ability in optical equipment bearing design. This ensures highly valuable access to Carter’s R&D facilities including the UK’s most advanced bearing simulation software – a critical part of the process of selecting the best design of thin section bearings for today’s optical applications.

Why are Silverthin Bearings ideal for Optical Systems?

Silverthin thin-section bearings were originally developed for defence applications as engineers sought more precise ways to rotate more sophisticated optical equipment with optimum speed and accuracy. Most high-tech optical tracking systems demand components which enable engineers to optimise weight and space savings, combined with very high positional accuracy and Silverthin bearings match this criteria. The combination of outstanding stiffness and excellent torque performance, housed in a compact and lightweight thin cross-section package means that Silverthin bearings are the preferred solution for many OEM’s for both civilian and defence applications.

What are todays’ specific applications for Silverthin Bearings?

Some examples of key optical applications include Gyro-Stabilised Gimbal Platforms. These sophisticated stabilisation systems are used in cameras, sensors, or other payloads helping to maintain a steady orientation whilst eliminating unwanted vibrations or movements. They consist of three main components; gyroscopes, sensors and motors. The gyroscopes measure the angular velocity of the platform, detecting any changes in orientation. The sensors provide additional feedback on the platform’s position, whilst the motors adjust the orientation of the gimbal in real-time counteracting any disturbances, keeping the camera or payload, stable and level. This technology allows for smooth and steady footage or data collection, even in challenging environments such as moving vehicles or turbulent conditions. Today these platforms are widely used in film production, aerial photography, surveillance and remote sensing to capture high-quality, jitter-free images and data.

Orbital Camera Rigs These specialised devices are used in filmmaking and photography to capture dynamic, sweeping shots with a circular or orbital motion and typically consist of a camera mounted on a rotating arm or track system that allows smooth movement around a central point or axis. By controlling the speed and direction of rotation, filmmakers can create stunning visual effects, such as circling around a subject or object, revealing a panoramic view, or simulating the sensation of orbiting in space. They are commonly used in cinematic productions, such as feature films, commercials, music videos and documentaries, adding dramatic movement and depth to shots, immersing viewers in the scene. The ultra-slim Silverthin design minimises the space required for the bearing assembly allowing for the most compact and lightweight camera rigs, optimising the key benefits of portability and manoeuvrability.

Laser Rangefinders – These devices measure the distance between the rangefinder and a target by emitting a laser beam and measuring the time it takes for the beam to reflect off the target and its return to the rangefinder. This measurement is based on the speed of light allowing for highly accurate distance calculations essential to applications such as; surveying, construction, hunting, golfing and military, where precise distance measurements are essential.

The key advantages are; rapid measurements, long range capability, high accuracy, so they are highly valuable to professionals and enthusiasts alike. Thin section bearings are utilised in laser rangefinders for a number of reasons; compact design means smaller, lighter devices, high-precision and accuracy which is essential for maintaining alignment of optical components within the rangefinder while low friction characteristics contribute to smooth operation, minimising any disturbances to laser beam alignment.

IR (Infrared) Imaging Systems This technology captures and visualises infrared radiation emitted by objects or environments, detecting the heat emitted by objects and converting it into an image which is visible to the human eye, or to other sensors for analysis. IR systems are used in various applications including; surveillance, security, medical imaging, firefighting and thermography where they detect temperature variations, identify objects in low-light or obscured conditions. They also provide valuable insights into thermal patterns and anomalies. As previously mentioned, these systems benefit from thin section bearings; compact, lightweight design which means smaller and more portable IR cameras, without compromising performance.

Other Applications for Thin Section Bearings?

Thin section bearings are also ideal for smooth action in articulating parts such as in the elbows of robotic arms and other similar articulating joints and can also be used in work-holding devices, such as turntables, indexing and rotary tables. Carter Manufacturing can provide application advice on all aspects of Silverthin Thin Section bearings, so are well placed to deal with design challenges where space is at a premium and repeatability, combined with absolute and longevity is vital over prolonged periods of time. More at: https://www.carterbearings.co.uk/bearings/thin-section-bearings