Stuttgart, 24 August 2023 – TRUMPF spin-off Optimate is consist-

ently developing its solution for AI-supported feasibility analysis

and part optimization: the cloud-based software, which can be used

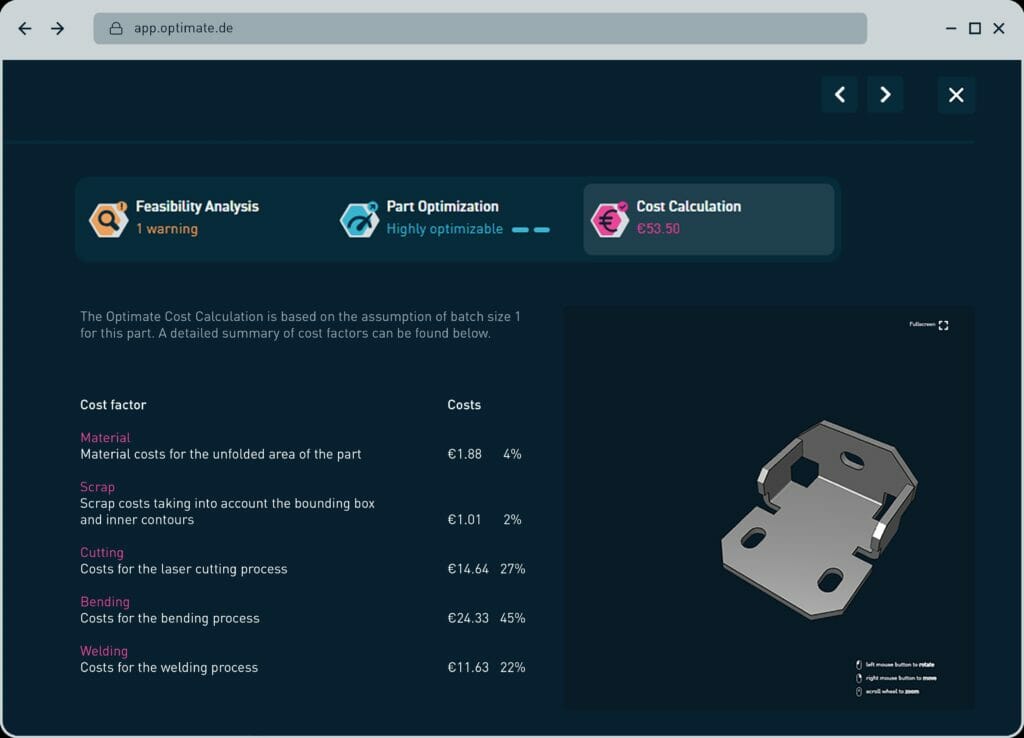

both as an App and CAD plug-in, now has an integrated cost calculation. Job shoppers and OEMs who produce and design sheet metal based products now only need one click to calculate the

costs of their parts.

With the Optimate App, product designers and sheet metal processing companies can identify defective parts in advance and adjust them, if necessary, even before they enter production. In addition to analyzing individual parts, assemblies with up to 25 individual parts can also be checked for feasibility and optimization potential. So far, the App has given a percentage indication of the potential savings of the optimized design compared to the existing variant. This was already a good indicator to determine the changed production costs. Regarding the individual manufacturing costs, the indicator held potential for optimization of the product.

‘With the introduction of the integrated cost calculation, this is now even

easier and more precise’, emphasizes Jonas Steiling, CEO at Optimate.

‘Our users receive the specific price for their sheet metal parts at the push of a button.’

Identify cost drivers within seconds

The calculated sum is based on the contributing cost factors for material, scrap and the manufacturing process, i.e. the complete sheet metal processing from laser cutting to bending and welding. ‘When considering the overall costs, it must of course be taken into account that not only

the material used is decisive, but also the design and the process steps required for it’, specifies Jonas Steiling. ‘Users can rely on our concentrated sheet metal knowledge here: all cost parameters are based on the specific know-how of our parent company TRUMPF, which has grown

over decades.’

In addition to the material costs, costs for scrap, set-up, and production

times as well as machine hourly rates are also included. Based on the

classification, companies in sheet metal processing can then break down

the costs for the detailed product processing steps. Once the cost drivers have been identified, optimization potential can be derived from this information.

Customer profile for precise cost measurements

Users can also create their own profile in the Optimate App. The infor-

mation stored with respect to machinery and tools is then also used for optimization and individual cost calculation. With highly precise data entries for machines, production processes and materials, the results for design and costs will be even more accurate.

Cross-departmental cost transparency

Such cost forecasts then benefit not only the designers themselves, who

can identify possible cost drivers already in the development process,

but also other areas, such as purchasing, controlling and cost calculation

for sales.

This makes it easy for buyers and job shoppers to calculate the costs of

sheet metal parts online. In the blink of an eye, the sales department can

create suitable offers for even the smallest series or individual parts in a

timely manner and without much effort.

‘The benefits range from accelerated development processes and long-

term planning, reliability in production to solid price and quotation calcu-

lation – and all that in a matter of seconds’, Optimate CEO Jonas Steiling concludes by referring to the ‘Konstruktionsleiterforum’ on 19 October in Wuerzburg. Optimate will present its new feature to a wider professional audience for the first time. ‘We are excited about the response and are already looking forward to many interesting discussions on the topic of digitalization in sheet metal processing.’

Optimate GmbH

Lautenschlagerstr. 16

70173 Stuttgart

[email protected]

www.optimate.de